Nige

Senior Member

Were the free lengths within spec.?The springs in the control valve I did not replace or test under load.

Did you do the adjustment procedure.?All the detents, cables and linkages seemed to be ok.

You could remove the axles from both tandems. If it was an H-Series or later then alternatively you could remove the lower drive shaft to the differential but you can't do that on a G.Also I’m really not sure how I’m going to do these test because of it wanting to stall in 1,2,3?

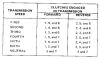

At the very least you need results for pump pressure, direction clutch, & speed clutch in neutral. The results for pilot pressure & transmission lubrication pressure might also be revealing.

You should ensure that all machine systems are at normal operating temperature before you take pressues. If the numbers you posted above were with the machine relatively-speaking cold those measured pressures should reduce even further when it reaches operating temperature.

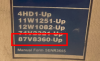

Did you open up the pump.? The 285psi you measured is significantly below the bottom of the spec considering that it's 310+/-10psi. I would suggest first having a look inside the pump before you go adding shims in an attempt to increase the pressure. Do you have any idea how accurate are the gauge/gauges you are using for measurements.?