kshansen

Senior Member

- Joined

- Mar 11, 2012

- Messages

- 11,165

- Location

- Central New York, USA

- Occupation

- Retired Mechanic in Stone Quarry

Okay got it if you find out that'd be really appreciated. Im not a super safety guy or anything and I do stupid stuff all day long but for this is one thing that concerns me because I been seeing way to many hitch failures more and more over the years and personally know a few it happened to so I do at least want to this right. Thanks buddyMy chart is at work, please stay tuned.

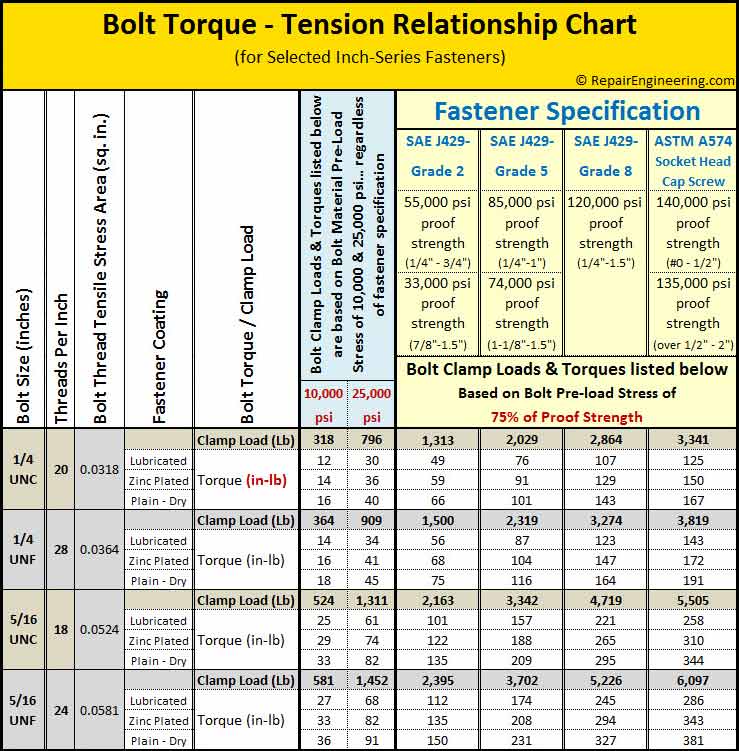

FWIW 120-140 ft. lbs may be the proper torque, but use a torque wrench.

Many times I set the wrench, and I'm pulling and pulling, and wondering "when is it gonna click",

making it much tighter that I would have done "freehand".

Make sure you also clean under the head, and where the nut/washer seat, so there is no relaxing

after torquing.

CAT discusses this in detail for applying crawler shoes/plates IIRC.

Oh wow thats perfect thanks! I wonder if using a little thread lock would affect the dry/wet torque? And yeah I mean personally I would known to overtighten everything so I'm not worried about not using one but looks like on the dump truck I'll I'll to go to over 400 lbs so I'll use one. That's gonna be fun to do with the amount of room I got due to the way the plate is set lolHere is a grade 8 bolt torque chart---one thing to notice is the wet/dry torque limits.

Rod, main & cylinder head bolts are figured at a wet limit, assembly lube on threads

and under heads of bolts & nuts.

*

Now one that will drive everyone up the wall----I've assembled Shortened/lengthened

70 some plus truck frames and consider myself some what of a authority on the issue.

I've never torqued a frame bolt or nut-----That's what my Snap On Shock Wave was for,

never had frames coming apart, bolts snapping or any of that jazz. Someone show me

a frame shop that torques frame bolts--Utility doesn't do it assembling on repair.

*

Anywho here's your bolt chart.