Nige

Senior Member

Machine Serial Number would be a good start ...... finding an Electrical Schematic isn't hard once we have that.

machine serial number would be a good start ...... Finding an electrical schematic isn't hard once we have that.

Machine Serial Number would be a good start ...... finding an Electrical Schematic isn't hard once we have that.

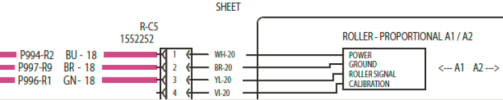

hi PopArcher,to enable high flow on C series machines a connection must be made across pin numbers F and G at the connector on lift frame this is usually done via the work tool electrical circuit see below or post number 16 above

View attachment 154658

to enable cont flow hold the cont flow button 6 below and operate the thumb wheel to its full extent then release button 6 and within 2 seconds release the thumb wheel this should enable high flow with the indicators in overhead panel lit up

View attachment 154659View attachment 154660

Understood Mark, Thanks. I may have an issue then as mine would not run in continuous mode until I installed the 107$ dummy cap on the new aux plug in, the old one was crushed when I bought the machine..?? And the high flow indication will not stay lit. I am headed to the farm for the next week and will get to work with it some more. Thanks again for your time. Will update you with progress or not..

Nige, we are having a similar issue today. Washed the machine and the only thing not working is the thumb rocker. We have no flow and the engine doesn't bog down.

Our SN is: ZSA03281

It was working all morning. Please Advise