-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone know how to disassemble tensioner cylinder on tak TL140

- Thread starter jimpad

- Start date

heymccall

Senior Member

CM1995

Administrator

- Joined

- Jan 21, 2007

- Messages

- 13,382

- Location

- Alabama

- Occupation

- Running what I brung and taking what I win

Just a safety note to anyone new to track tensioners -

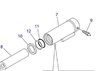

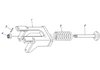

DO NOT take the key #5 and the nut #4 off of the rod #2 holding spring #3 in place. DEATH or wishing you were dead are probable consequences. That part of the assembly needs to be taken apart in a shop by qualified mechanics that have the proper press to do it safely.

DO NOT take the key #5 and the nut #4 off of the rod #2 holding spring #3 in place. DEATH or wishing you were dead are probable consequences. That part of the assembly needs to be taken apart in a shop by qualified mechanics that have the proper press to do it safely.

Last edited:

heymccall

Senior Member

Just a safety note to anyone new to track tensioners -

DO NOT take the key #5 and the nut #4 off of the rod #2 holding spring #3 in place. DEATH or wishing you were dead are probable consequences. That part of the assembly needs to be taken apart in a shop by qualified mechanics that have the proper press to do it safely.

Yes, this assy requires special tooling to safely disassemble, but, that action isn't required to service the cylinder.

heymccall

Senior Member

#8 is just a polished rod. No thread, no grooves, nothing, save for indent on end toward idler.

Once rod (8) is removed, inner seals (11&12) can be swapped out.

As for source of image, here is parts manual pdf ... https://www.google.com/url?sa=t&sou...FjABegQIBhAB&usg=AOvVaw3L7W4pD6aiMWlCb3Nb9GlY

Once rod (8) is removed, inner seals (11&12) can be swapped out.

As for source of image, here is parts manual pdf ... https://www.google.com/url?sa=t&sou...FjABegQIBhAB&usg=AOvVaw3L7W4pD6aiMWlCb3Nb9GlY