-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

988B hyd problems

- Thread starter gladiatore

- Start date

gladiatore

Well-Known Member

They say manual said is 813 psi but I don't trusht them can you please tell me which is the pressure for that accumulator in psi?

kshansen

Senior Member

- Joined

- Mar 11, 2012

- Messages

- 11,169

- Location

- Central New York, USA

- Occupation

- Retired Mechanic in Stone Quarry

They say manual said is 813 psi but I don't trusht them can you please tell me which is the pressure for that accumulator in psi?

Like lantraxco says:

"Might pay to ask around any local rock quarries, mines, large contractors, somebody has to have the kit to charge accumulators, maybe even a welding supply? They'll at least have the nitrogen and the regulator...."

I have to wonder how a Cat dealer somewhere in the county could not have even a homemade kit to charge an accumulator! Where I worked we had a kit from back in the early 1970's. I personally adapted it to be able to charge suspension cylinders on Cat haul truck, just an extra hose valve and pipe tee. Also the last full day I worked I used this same kit to charge an accumulator on the hydraulic control for a Nordberg crusher. Also used to charge accumulators on an El-Jay crusher when we had one of those and another time it was used on the accumulator of a hydraulic hammer mounted on a Kobelco excavator.

Other than the regulator and the cylinder of nitrogen and a couple gauges the most important part would be the chuck that connects to the fitting on the cylinder. I don't think I have the Cat part number for that but if I can locate it I'll post that information.

kshansen

Senior Member

- Joined

- Mar 11, 2012

- Messages

- 11,169

- Location

- Central New York, USA

- Occupation

- Retired Mechanic in Stone Quarry

gladiatore

Well-Known Member

Thanks a lot ken Im sending this info to the "experts" from caterpillar mexico

gladiatore

Well-Known Member

Ok I have accumulator carged , Monday I go to change again in machine wish me luck, I really hope this fix the problem

gladiatore

Well-Known Member

No lantraxco, i just took out all nitrogen, in the quarry, for be realistic i was worried carrie accumulator in truck with charge of nitrogen

kshansen

Senior Member

- Joined

- Mar 11, 2012

- Messages

- 11,169

- Location

- Central New York, USA

- Occupation

- Retired Mechanic in Stone Quarry

No lantraxco, i just took out all nitrogen, in the quarry, for be realistic i was worried carrie accumulator in truck with charge of nitrogen

Nitrogen is an inert gas so no fire hazard as long as the accumulator is not flopping around so the fill valve on top gets busted should be no problem. Where did you finally get it charged? Did my posting of the kit information wake up the people at the Cat dealer? "OH! That's what those things are for!"

Sometimes dealer mechanics are not that up on things. One time years ago we had a big Allison transmission in the shop and for some reason management felt the need to bring in Allison dealer to replace converter parts. We had done many of the 6000 series but this was an 8000 series other than size of parts identical job. Well Norm and I spent most of the time showing him how to do the job!

gladiatore

Well-Known Member

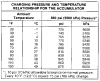

Yes I spent all morning yesterday in Cat dealer, showing them how to use the equip and finally I needed do the charge because they dont had idea how top do it, also I checked temp from cilynder and temp from the space where we was located was 25 celcius so i put on it 813 psi, now really i hope with this machine works good, because as always now the client is crazy about his machine, and start say stupid things about my work, so I really hope it works, thanks for the help guys, I will keep you informed what happened

gladiatore

Well-Known Member

And of course eventos i did 99% of the work they charged me with a 400 dollars bill

kshansen

Senior Member

- Joined

- Mar 11, 2012

- Messages

- 11,169

- Location

- Central New York, USA

- Occupation

- Retired Mechanic in Stone Quarry

And of course eventos i did 99% of the work they charged me with a 400 dollars bill

Too bad you weren't closer to me in Central NY. I'll bet my ex boss would let me borrow the kit and tank of nitrogen. I'd do the job for free or maybe make you buy me dinner somewhere! I'd even let you ride in the sidecar to get there!

Maybe you should ask them for a job, sounds like they could use a few new mechanics!

gladiatore

Well-Known Member

Well I install accumulator and same, you need push brake for work so I think is the valvle I change the other day, but now started with a new illness, I was trying to make it work push the clutch and I hear a sound like broken hose and stopped don't move forward or reverse, now really I'm sick I don't know what I broke that now doesn't moves please help with that I'm tired and bored

gladiatore

Well-Known Member

Well this machine is driving me crazy still keep the problem, I'm just thinking why I need push the brake when hot to release power to lift and bucket ? Where the hell is the problem with this machine, also client is making me angry about money (even so far I just ask for my expenses, gasoline hotel, toll post and food )

kshansen

Senior Member

- Joined

- Mar 11, 2012

- Messages

- 11,169

- Location

- Central New York, USA

- Occupation

- Retired Mechanic in Stone Quarry

Seems like you have swapped out just about every component of the system and none have made a noticeable change. The only thing I don't recall you doing anything with is the pump itself. Not saying that is the problem but would be nice if there was a way to test that to be sure. Where I worked we had a flow meter that could be hooked to a pump to check the flow and pressure a pump was putting out. Don't think anyone there these days even knows what that blue box in the yellow cabinet is!

To refresh my memory, did you open up the two filters mounted on the inside of the frame on the right side of the machine? I seem to recall the tops having a large socket headed plug in the center and six bolts holding the tops on. The covers are about 4 inches across the flats as I recall. They are, I believe, screen type filters that would catch any big parts coming out of the pumps.

Wish I could offer more help but this one is leaving with more questions than answers.

One more thought. Have you opened up any of the valves you did remove to install the ones off the other machine to see if there was anything obvious wrong with them. I'd look very close at spools for any small orifices that could be plugged.

I had a transmission control valve on a 988A onetime that had a very small orifice with a piece like a small grain of sand in it that stopped the transmission from going into gear.

To refresh my memory, did you open up the two filters mounted on the inside of the frame on the right side of the machine? I seem to recall the tops having a large socket headed plug in the center and six bolts holding the tops on. The covers are about 4 inches across the flats as I recall. They are, I believe, screen type filters that would catch any big parts coming out of the pumps.

Wish I could offer more help but this one is leaving with more questions than answers.

One more thought. Have you opened up any of the valves you did remove to install the ones off the other machine to see if there was anything obvious wrong with them. I'd look very close at spools for any small orifices that could be plugged.

I had a transmission control valve on a 988A onetime that had a very small orifice with a piece like a small grain of sand in it that stopped the transmission from going into gear.

gladiatore

Well-Known Member

Nige

Senior Member

The procedure referred in the photo above is for removal of the PUMP DRIVE once the Steering & Brake Pump has been removed, not to remove the pump itself.

Why did he want you to remove the pump drive..?

Did he in fact want you to remove the pump drive..?

I am confused. Not difficult I hear you say, but the procedure shown in that photo above bears no direct relation to a pump .........

Why did he want you to remove the pump drive..?

Did he in fact want you to remove the pump drive..?

I am confused. Not difficult I hear you say, but the procedure shown in that photo above bears no direct relation to a pump .........

kshansen

Senior Member

- Joined

- Mar 11, 2012

- Messages

- 11,169

- Location

- Central New York, USA

- Occupation

- Retired Mechanic in Stone Quarry

Nige, that makes two of us being confused as to why he was sent the pump drive removal instructions.

If there was a problem with the drive, failed splines or such, then there would be loss of steering at the same time as the loss of pilot pressure.

I believe this machine has the Tyrone gear pumps. I know they can get some wear on the end plates that might not be real obvious to some and that will cause a large loss of pressure and flow when warm. Not to mention worn bushings letting the gears cut into the housings.

If there was a problem with the drive, failed splines or such, then there would be loss of steering at the same time as the loss of pilot pressure.

I believe this machine has the Tyrone gear pumps. I know they can get some wear on the end plates that might not be real obvious to some and that will cause a large loss of pressure and flow when warm. Not to mention worn bushings letting the gears cut into the housings.