leadfarmer

Well-Known Member

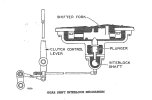

Drained the wet clutch compartment last night.

Suction screen was clogged and sucked to the point of failure.

Pulled out a bunch of pieces of what looks like clutch material? It is non-metallic.

Anything I should be worried about? The clutch works fine. I was planning on opening the inspection cover on the top side to to have a look inside.

Planning on replacing the screen and filling it with fresh Cat TDTO 30.

Whoever thought a 1-1/4" allen was the right tool for the drain plug sucked! 3/4" or 1" square pocket would of been much better.

Suction screen was clogged and sucked to the point of failure.

Pulled out a bunch of pieces of what looks like clutch material? It is non-metallic.

Anything I should be worried about? The clutch works fine. I was planning on opening the inspection cover on the top side to to have a look inside.

Planning on replacing the screen and filling it with fresh Cat TDTO 30.

Whoever thought a 1-1/4" allen was the right tool for the drain plug sucked! 3/4" or 1" square pocket would of been much better.