JOHN140

Active Member

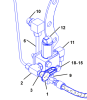

I’m having some trouble with my 140m B9d1908 13415 hrs. Hoping ifor some input from you guys. Something in the drive train(best I can tell) is making the machine not ride as smooth as it should when working along with extremely rough up and down shifts. It’s a very small bounce or something but I feel it all day every day makes finishing very tough. I’ve swapped the wheels and tires with another machine and had no effect. I’ve had the tandem bushings or wearable parts replaced with no effect. Tandems needed reworked anyways but didn’t help this issue. Recently I’ve been thinking it may be something to do with the transmission. The other day reading random threads on HEF I came across a thread concerning troubleshooting a transmission(can’t remember the thread name). Someone advised capping the supply line to diff lock valve to see if pressure was being lost through the valve. The next I did this to my machine and fixed all the issues I’ve been dealing with. The line I capped is the one that runs from the transmission(connects next to pressure relief valve) to the diff valve. I was surprised that without oil supply the diff is unlocked. Anyways the blade feels like it should with this line capped. Will this hurt the machine to run this way until I can get the valve replaced? Can we assume the valve is bad? Are there any other parts in this diff lock circuit that could be responsible for this(check valves,etc). Any thoughts you guys have on this are greatly appreciated.