JUMPIN JIMMY

Member

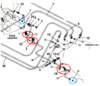

ive an older 613 Cat scraper. Trying to find s/n (under operators platform on frame?). After sitting for a period of time, i had to let it sit idling in gear for about 15 min, with bowl on ground, before trans would engage. I am noticing driveshaft from torque converter to trans is turning very slowly, regardless of engine rpm. Does torque converter pump trans fluid to torque converter? A construction mechanic mentioned maybe torque converter pump is not pumping fluid, and possibly try unhooking converter to trans oil line and pouring fluid into torque converter, so it will start pumping. Also, nobody is home in fourth gear, however the lower three work fine. i'm assuming that problem would be in the trans. any advice with these issues?

Thank You for your consideration! Jim

Thank You for your consideration! Jim

![scraper[1].jpg scraper[1].jpg](https://www.heavyequipmentforums.com/data/attachments/223/223327-e940438ea7aa8ba537f3735e9ae248cd.jpg)

![scraper2[1].jpg scraper2[1].jpg](https://www.heavyequipmentforums.com/data/attachments/223/223328-f313e40a233872ca3520e5458a0916db.jpg)

![scraper3[1].jpg scraper3[1].jpg](https://www.heavyequipmentforums.com/data/attachments/223/223329-03d1aad68ec0553f50ac2d0439011863.jpg)

![scraper4[1].jpg scraper4[1].jpg](https://www.heavyequipmentforums.com/data/attachments/223/223330-ef62470f9d9d2fe2aaf466bfe00ffaef.jpg)