S# A83597

I am getting an irrational fault code of E15 that seems to have no regularity to it. It may go off several times a day, or not at all, which has been making this cumbersome to say the least. When the code does come up, the engine derates and the operator kills the machine which evidently is resetting the computer. I got there Friday to check it out and the code did come up for me, a flashing E15 with a flashing exclamation point. The problem I had was when I tried to narrow down the actual fault code itself, I would push the exclamation point button the code would clear from the screen...…...so I haven't figured out how to get there.

So this is where you Komatsu experts can shine for me. Through some research I have figured out that the E15 is engine sensor related, but I need the CA number to narrow this down. Tell me what I am doing wrong and how do I get to what I want to see?

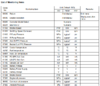

I have included a pic of the panel for reference.

I am getting an irrational fault code of E15 that seems to have no regularity to it. It may go off several times a day, or not at all, which has been making this cumbersome to say the least. When the code does come up, the engine derates and the operator kills the machine which evidently is resetting the computer. I got there Friday to check it out and the code did come up for me, a flashing E15 with a flashing exclamation point. The problem I had was when I tried to narrow down the actual fault code itself, I would push the exclamation point button the code would clear from the screen...…...so I haven't figured out how to get there.

So this is where you Komatsu experts can shine for me. Through some research I have figured out that the E15 is engine sensor related, but I need the CA number to narrow this down. Tell me what I am doing wrong and how do I get to what I want to see?

I have included a pic of the panel for reference.