You need to be real careful using Muriatic (Hydrochloric) acid in cooling systems. Muriatic acid attacks every metal, as well as the rust. About 3% solution is the maximum you want to go - and don't leave it to soak!

I don't believe Vinegar is strong enough to remove heavy corrosion in a cooling system.

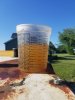

I use Citric acid. About 5% to 10% solution, depending on the level of corrosion. It's safe (it's a food preservative, added to a vast number of foods, including bread), no need to worry about acid burns as with Muriatic acid, no need to worry about splashes etching everything the splashes land on, and no need to worry about kids finding it, and playing with it. And no chlorine fumes, as you get with Muriatic acid.

Citric acid can be left in the cooling system overnight, and even for a couple of days if necessary. It simply dissolves rust, and doesn't badly etch the base metal, as Muriatic does. It doesn't eat copper or aluminium and doesn't adversely affect hoses. It does help to pressure-wash the cooling system once you've emptied the Citric acid out.

For heavy black scale though, you would need a dose of Muriatic acid to clean that stuff out.

FWIW, Cat claimed many years ago that a 1/16" coating of scale on a liner or block will prevent 40% of the engine heat from escaping. Scale is the best insulation material since Asbestos!