631G

Senior Member

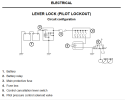

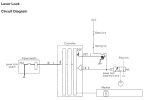

We have a Link Belt 3400Q long reach (SN:E718-9519) that sporadically will not resume hydraulic function when disengaging the safety lever in the cab. There doesn't seem to be any pattern to it. It will malfunction when the machine is hot or cold and from first start to 8 hours into shift. I thought that it might be the small switch that the lever actually moves when cycling it up and down but nothing really hanged after replacing it. I don't have a wiring diagram and given the machines age dealer support is a stretch at best. Could this be a sticking solenoid or spool possibly? I've read elsewhere that these machines weren't known to be the best on their wiring and given the intermittent nature of this issue I am leaning that way. Anyone else have this issue in the past or have any thoughts on where to look first? I am going to start looking on Ebay for shop manuals etc. see what's out there.