Hi All,

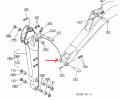

I've recently acquired a Kubota KX161-2 and looks as though the boom to dipper connection needs rebushed. Looking on Messick's, I'm not able to find a bushing for the part of the boom that receives the dipper (see attached image). Looking at the machine as well, it's tough to tell if there is a bushing at all. It almost appears that the boss is welded on and the connection is steel to steel.

Am I missing something here? If it is in fact a steel to steel connection, what are my repair options?

I've recently acquired a Kubota KX161-2 and looks as though the boom to dipper connection needs rebushed. Looking on Messick's, I'm not able to find a bushing for the part of the boom that receives the dipper (see attached image). Looking at the machine as well, it's tough to tell if there is a bushing at all. It almost appears that the boss is welded on and the connection is steel to steel.

Am I missing something here? If it is in fact a steel to steel connection, what are my repair options?