Komatsu D37 Identifying Master Pin vs. Master Link

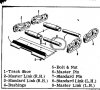

I have a Komatsu D37 that does not appear to have a master link on the track. The parts manual shows some tracks to have a master pin rather than a master link. The manual's illustration of the master pin is very small and without detail. On the machine itself, I can't really see any visual difference in the pins on the track. I need to remove the track to replace the seal on the track adjuster. What do I do?

I have a Komatsu D37 that does not appear to have a master link on the track. The parts manual shows some tracks to have a master pin rather than a master link. The manual's illustration of the master pin is very small and without detail. On the machine itself, I can't really see any visual difference in the pins on the track. I need to remove the track to replace the seal on the track adjuster. What do I do?

Last edited: