Andrey, how does this machine Steer? Is Steer slow as well?

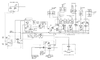

Although these older units do suffer from voltage drop, you may want to eliminate the hydraulic system first. It will be easier accomplished than electrical diagnostics.

The fact that your drive is working good suggests that the voltage to your Anti-Stall Board and Joystick for Drive, Brake Release and Steer is adequate. Chances are the supply to the boom function controllers is OK as well. A quick check would be to attach a Voltmeter to the + and - terminals of the Secondary Boom UP/DOWN Joystick, Engine Running, Foot on the foot pedal, Note the Voltage without stroking the Joystick (approx 12.5 to 14 volts) and then fully stroke the Joystick fully in the UP direction. If the Voltage at + and - drops down to less than 11 Volts then yes, the functions will be slow. Cables coming up the boom, E-Stop, Foot-Switch and connections are certainly suspect.

This machine is a 2WD Deutz machine?

Back to the hydraulics.

There are two pumps, a pump for Drive and a pump for Boom Functions.

It could very well be the function pump that is tired.

With a pressure gauge at the test port on the Function Manifold, there should be approximately 152 Bar when operating Platform Level all the way UP and continue to hold the switch in the UP position, as well as, operating Platform Rotate completely Clockwise or Counter-Clockwise and holding the switch.

If there is not enough pressure, you may try adjusting the Pressure Relief Valve to achieve the 152 Bar (2200psi).

but, Let us know how the Steer is working. This will tell us boatloads about the cause.

View attachment 164807