Blueacre

Well-Known Member

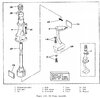

I recently bought a Clark C500, 5000 lb pneumatic tire model with a Waukesha gas engine. When i bought it The oil pressure and temperature gauges were not working but it runs fine. I just finished refurbishing the entire wiring harness but the oil pressure gauge was still not working so I replaced it with a mechanical gauge with a 1/8" tube from the sensor location to the gauge. Still no oil pressure. This engine has the bypass oil filter system with a short line running to the filter from a tee on the side of the block where the oil pressure sender is located. It also has a long hose running from the filter to the opposite side of the block. I disconnected the short hose from the block to the filter and ran the engine - I only get a real small dribble of oil from the hose - took 30 seconds to fill half a cup with oil.

Seems like there is almost no oil pressure at this location where the oil pressure is connected yet the engine the engine runs smoothly at all rpms with no noise I would expect to hear noise from rod bearings or rocker arms with low oil pressure.

Appreciate if anyone with knowledge of the Waukesha engines could give me some pointers on trying to figure out what the problem is.

Is there any possibility of something blocking the oil flow to the pressure gauge and filter connection location but the rest of the engine still getting oil ?

Is there another location I can check oil pressure and/or flow to see if the oil pump is working ?

Seems like there is almost no oil pressure at this location where the oil pressure is connected yet the engine the engine runs smoothly at all rpms with no noise I would expect to hear noise from rod bearings or rocker arms with low oil pressure.

Appreciate if anyone with knowledge of the Waukesha engines could give me some pointers on trying to figure out what the problem is.

Is there any possibility of something blocking the oil flow to the pressure gauge and filter connection location but the rest of the engine still getting oil ?

Is there another location I can check oil pressure and/or flow to see if the oil pump is working ?