Shimmy1

Senior Member

I'm gonna say it, bottom rollers were shot to hell 1000 hours ago, and probably contributed to hammering the pins out. I'd be curious to know how much lube is left in the links.

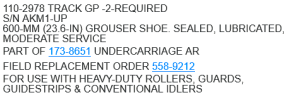

OK, so the track groups are only moderate service, not heavy duty, and based on the text below where did all the rock guards go.?Yes nige exactly the same.

Rough riding for sureI'm gonna say it, bottom rollers were shot to hell 1000 hours ago, and probably contributed to hammering the pins out. I'd be curious to know how much lube is left in the links.

Nige, machine has never had bottom guards. Looking for last undercarriage report.OK, so the track groups are only moderate service, not heavy duty, and based on the text below where did all the rock guards go.?

View attachment 304388

I'm with Shimmy. What % wear are the track rollers showing on the undercarriage report.? Well over 100 I would have thought.

TBH unless you need loads of flotation I'd say those shoes are probably about 2" wider than they need to be.

The roller flanges aren't hitting the pin boss on the links too bad yet though.I'm gonna say it, bottom rollers were shot to hell 1000 hours ago, and probably contributed to hammering the pins out. I'd be curious to know how much lube is left in the links.

Track tension was too tight on the LH side and REALLY tight on the RH side according to the report. No idea whether this is typical throughout the life of the U/C or not. I also wonder if the tension has any relation to the RH track roller wear.? From the photos it appears as though the link pin boss wear is far higher on the RH side of the tractor than it is on the left.From the report it is clear that the links have worn faster than the rest of the components, but I certainly don't know what would cause that other than possibly being run too tight.

It was March of 2023 when he did measurment . Told me why he did not do right side but I don't remember. Any way I had just pumped the right track out and never got around to letting off some grease. Machine been sitting since. Start every few weeks to keep batteries up.Interesting that the U/C report doesn't list the wear for the RH track rollers but does for the LH ones. Any idea why.?

Track tension was too tight on the LH side and REALLY tight on the RH side according to the report. No idea whether this is typical throughout the life of the U/C or not. I also wonder if the tension has any relation to the RH track roller wear.? From the photos it appears as though the link pin boss wear is far higher on the RH side of the tractor than it is on the left.

It means that something has been cancelled/superceded/improved and the original is no longer available.Nige what is a field replacement order?

I would agree 100%Bottom rollers worn is likely causing the wear pattern on the links. You can see it well in the last picture on post #15. I think their % numbers on the report are a bit conservative, but I’ve found that’s generally the case.