D5Dan

Well-Known Member

I have a Cat D5 (no letter) Machine Serial #84H493

Happy to report I’ve finally pulled the blade lift cylinders and got them down at our local hydraulic guy getting new seals installed (long over due).

I’m also seeing some items I can address while I’m in reworking the leaking seals.

Checking the top (back) right corner of my blade, tag is gone. With some sanding/wire wheel work I “think” I’m see a stamping of 92H354 (with the 354 look “trailing” or added). Blade is 9’6” wide by 3’ tall straight blade with a tilt cylinder on the left-hand side.

I believe the manual I need is?:

CAT Caterpillar 5A 5S Bulldozer Parts Book Manual 90/91/92/93H1 12/73 UE070055

Just curious if I’m going after the correct manual?

And/or could this blade be the correct one for my machine? (aside from repairs/hacks, it looks the part)

Couple follow-up numbers I have found:

On the lift blade cylinder head I see stamping 5J8161.

Measurements lead me to believe the cylinder mount bearing/bushing is 4J6374

Then each saddle mount area also had bearing halves – with Cat stamping #4J6326 (and are VERY well worn!!)

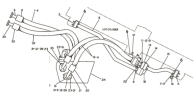

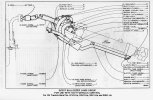

I’d like to have Cat part numbers for the four hoses that come off the connector block under the hood/on top of motor and go to each lift cylinder. I got one hose off machine today and will take to hydraulic guy tomorrow…but without the manual I feel like I'm flying blind.

I did find this thread helpful (so thank you all!):

www.heavyequipmentforums.com

www.heavyequipmentforums.com

Happy to report I’ve finally pulled the blade lift cylinders and got them down at our local hydraulic guy getting new seals installed (long over due).

I’m also seeing some items I can address while I’m in reworking the leaking seals.

Checking the top (back) right corner of my blade, tag is gone. With some sanding/wire wheel work I “think” I’m see a stamping of 92H354 (with the 354 look “trailing” or added). Blade is 9’6” wide by 3’ tall straight blade with a tilt cylinder on the left-hand side.

I believe the manual I need is?:

CAT Caterpillar 5A 5S Bulldozer Parts Book Manual 90/91/92/93H1 12/73 UE070055

Just curious if I’m going after the correct manual?

And/or could this blade be the correct one for my machine? (aside from repairs/hacks, it looks the part)

Couple follow-up numbers I have found:

On the lift blade cylinder head I see stamping 5J8161.

Measurements lead me to believe the cylinder mount bearing/bushing is 4J6374

Then each saddle mount area also had bearing halves – with Cat stamping #4J6326 (and are VERY well worn!!)

I’d like to have Cat part numbers for the four hoses that come off the connector block under the hood/on top of motor and go to each lift cylinder. I got one hose off machine today and will take to hydraulic guy tomorrow…but without the manual I feel like I'm flying blind.

I did find this thread helpful (so thank you all!):

D6C Dozer Blade Lift Cylinders

On my D6C 10K 6516 tractor that I got recently, I didn't get a parts book with the machine & need to re-chrome the rods (badly scored) & repack the both blade lift cylinders & was told by someone that there may be some identification on the outside of barrel which will identify it. I found a...

www.heavyequipmentforums.com

www.heavyequipmentforums.com