hi moderators if you think this Reply should be moved please do so

Mark

hi mark, please could you show me how to connect the et directly to the ecm?? that would be really handy.

Hi mrappels,it is quite easy to power up an ECM via a different power source than the machine. there are a couple of things to be aware of

1- the ECMs will run on either 12v or 24 volt

2- even though multiple power supply's and returns are indicated on electrical schematics only one B+ and one B- is required to operate the ECM for test purposes

3- generally 5 wires are needed for the ECM to communicate with ET

B+, B-,key switch B+,CDL + and CDL -

4- be aware that on highway trucks use different diagnostic plugs than machine diagnostic plugs

5- Cat uses a number different ECM's and some even look the same but the connection pin outs are different

Here is a list of common ECM's

ADAM 2 - has two forty pin connectors used ,as engine ECM

MAC- has one or two forty pin connectors ,looks the same as ADEM 2 ECM, used as machine system ECM

ADEM 3- has two 70 pin connectors used as engine ECM

ABL- Has one or two seventy pin connectors, looks the same as ADEM 3 ECM, used as machine system ECM

ADEM 4- has one seventy pin connector and one,one hundred and twenty pin connector, used for engine and machine systems

ADEM A4-E2 Has two 64 pin connectors used as engine ECM on later common rail engines (Perkins/Mitsubishi)

for the ADEM 2 ECM pin outs

B+ to pin#4 also connect to diagnostic connector pin#A

B- to pin#5 also connect to diagnostic connector pin#B

CDL+ to pin#9 also connect to diagnostic connector pin#D (green)

CDL- to pin#3 also connect to diagnostic connector pin#E (brown)

switched input B+ to pin#6

For MAC ECM

B+ to pin#1 also connect to diagnostic connector pin#A

B- to pin#2 also connect to diagnostic connector pin#B

CDL+ to pin#9 also connect to diagnostic connector pin#D

CDL- to pin#3 also connect to diagnostic connector pin#E

switched input B+ to pin#40

For ADEM 3 and 4 ECM (engine)

B+ to either 48,52 or 53 also connect to diagnostic connector pin#A

B- to either 63,65 or 67 also connect to diagnostic connector pin#B

CD+L to pin#8 also connect to diagnostic connector pin#D

CD-L to pin#9 also connect to diagnostic connector pin#E

switched input B+ to pin #70

For ADEM 3 and 4 (machine)

B+ to pin#1 also connect to diagnostic connector pin#A

B- to pin #2 also connect to diagnostic connector pin#B

CDL+ to pin #8 also connect to diagnostic connector pin#D

CDL- to pin#7 also connect to diagnostic connector pin#E switched input B+ to pin #58

for A4 E2 ECM

B+ to pin#1,2,9 or 10 also connect to diagnostic connector pin#A

B- to pin #7,8,15 or 16 also connect to diagnostic connector pin#B

CDL+ to pin #23 also connect to diagnostic connector pin#D

CDL- to pi #24 also connect to diagnostic connector pin#E

switched input to pin#40

some cat part numbers that may be useful

diagnostic connector P# 8T8736

A3 ECM connector 160-7689

sockets for above 9x3402

A2 ECM connector 3E6286

A3 ABL ECM connector 160-7690

MAC ECM connector 101-0205

A4E2 ECM connector 245-1042

sockets for above 267-9572

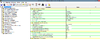

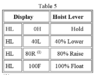

here is some screen shots of ECM ET stand alone Data