Thanks for all the input guys. I probably should have tagged this conversation onto my previous thread about building my lake - a lot of these questions have already been addressed there. I was just trying to see if a 955 would be up to the task, or if the crowd would think it's too small. I had previously asked about a 963

(Here) and came away with the impression it would be more than sufficient. Bottom line is, I can't afford a scraper AND the tractor to pull it. I only get one machine and I think it'll have to be a dozer / track loader. I'm still young enough, dumb enough, and energetic enough to put the hours in on the machine to get the job done - even if it does take a little longer than it should due to the distance I'll be pushing dirt. I also have a backhoe I'll be digging the keyway with, so have all that taken care of. And I'll plan to resell whatever dozer / track loader I get after the lake is done, so it just has to last me this summer..

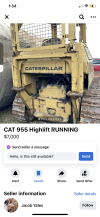

I went and looked at the 955L tonight. It's certainly a $7k machine, nothing more, perhaps less... Few questions I'll throw out here for feedback:

- Seemed to start and run fine. No excessive smoke or anything concerning there. Engine oil looked fine - I didn't get too far into checking any other fluids yet.

- It doesn't turn left. It goes straight just fine, and turns right just fine, but when you press the left foot pedal, it starts to turn, then quits. I've never run a dozer / Track Loader before, so I'll do my best to explain what I witnessed.. When going forward, then I pressed the left pedal, it seems to lose forward drive completely for a split second, then it feels like it engages the right track for a half second or so, then basically stops driving the right track. You can tell it's pushing that right track a little, but not hard enough to turn the machine. It's as if it starts to engage the right track, but then "Decides not to". I know it's not making any such decisions, but it was interesting I could feel it start to engage, then stop. Same happened in forward or reverse - no turning left.

- When pressing the right pedal, it seemed to do the same split second stop of drive, but then the left track engaged and drove hard like it should. Is that split second of no drive normal?

- It will drive straight, and push dirt, and turn right all day (or at least for 10 minutes).

- If I was going straight forward and really pressed the left pedal, the track would stop / drag. The left track brakes appear to be working.

- I noticed that the left pedal seemed to go basically all the way to the floor, while the right met enough resistance to stop a fair amount before the left pedal. Is this significant?

- My guess is that the drive clutch for the right track is weak? Let me know if you agree with that assessment. Is there a possibility it might just need adjustment? If so, and it's an hour or less to try that - I'll go back and work on it and see if I can get it working.

- Also noticed when in reverse in speed 3 (highest speed), it didn't seem to want to move until I was full throttle. And even then it seemed a little soft. Forward, all 3 speeds seemed to work fine.

- I watched a good youtube video of a guy pulling the brake / clutch pack out. Looked fairly involved, but not undoable. Any further input on that? Is it worse than it looks? I realize even if I was dumb enough to take this on, I'd have to find a shop to do the clutch / brake replacement. Anybody have an idea on parts cost?

- I think there's a chance I could pick this up for 1/2 the $7k listed price. Would you still avoid it at $3,500? I think I know the answer - I'm just trying to find something in my miniature budget here, and I'm not afraid to put some work in.

- Aside from the drive problem, it has a lift cylinder shooting fluid out, and a tilt cylinder with a slow leak. Undercarriage is about 50% - enough to get through my job for sure. I got caught up in checking out the drive problem, and forgot to write down the hours of the machine. Will be going back soon to look at that, get serial number etc.