-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

943 B It loses performance when warm.

- Thread starter cat951b

- Start date

sawmilleng

Well-Known Member

In looking thru the service documents from Nige, I find it quite startling to realize that Cat implements a BUNCH of controls within the pump/drive setup MECHANICALLY. When likely all of the controls could be implemented electronically thru computer control.

They must have been designed before the real push to move as much as possible to computer control finally came thru.

When did the first Cat hydrostatic crawler loaders hit the market? If they were in the early '80's I can see the reason for all the mechanical monkey motion in the pump controllers. (In 1980 I was fiddling with my first computer that had 8" floppy drives and zeroing sawmill hydraulic setworks servo valves with a nylon allen key because a metal key screwed up the magnetic field in the valve--all stone age electronics)

But the mechanical controls sure improved the return for the Cat service people.

I'd love to pick up a 955 loader but I'll run away screaming from anything with hydrostatic drive... unless it's fully electronic but then I probably couldn't afford it 'cause its too new...

Jon.

They must have been designed before the real push to move as much as possible to computer control finally came thru.

When did the first Cat hydrostatic crawler loaders hit the market? If they were in the early '80's I can see the reason for all the mechanical monkey motion in the pump controllers. (In 1980 I was fiddling with my first computer that had 8" floppy drives and zeroing sawmill hydraulic setworks servo valves with a nylon allen key because a metal key screwed up the magnetic field in the valve--all stone age electronics)

But the mechanical controls sure improved the return for the Cat service people.

I'd love to pick up a 955 loader but I'll run away screaming from anything with hydrostatic drive... unless it's fully electronic but then I probably couldn't afford it 'cause its too new...

Jon.

heymccall

Senior Member

Electronic ain't necessarily better. I've got over $60k in 2 separate hydrostat failures, between warranty and me, on our 953C, before it hit 3k hours. Not from electronics, but rather plumbing and parts issues. The plumbing and parts updates should keep it together from here on out. Yet my 943A and 963B just keep soldiering on, with no electronics to speak of.In looking thru the service documents from Nige, I find it quite startling to realize that Cat implements a BUNCH of controls within the pump/drive setup MECHANICALLY. When likely all of the controls could be implemented electronically thru computer control.

They must have been designed before the real push to move as much as possible to computer control finally came thru.

When did the first Cat hydrostatic crawler loaders hit the market? If they were in the early '80's I can see the reason for all the mechanical monkey motion in the pump controllers. (In 1980 I was fiddling with my first computer that had 8" floppy drives and zeroing sawmill hydraulic setworks servo valves with a nylon allen key because a metal key screwed up the magnetic field in the valve--all stone age electronics)

But the mechanical controls sure improved the return for the Cat service people.

I'd love to pick up a 955 loader but I'll run away screaming from anything with hydrostatic drive... unless it's fully electronic but then I probably couldn't afford it 'cause its too new...

Jon.

Hello everyone and I wish you a successful and happy New Year! Between the two holidays, I had time to deal with the above-mentioned machine. Unfortunately, I had a bad experience with it and found broken pieces of the 3rd piston in the oil sump. I am attaching a few photos of him and the wools. After that, I decided to remove the complete engine together with the Hidrostat and renew it...

Attachments

..Unfortunately, amore had already darkened, I was done with the disassembly and I didn't have time to inspect the engine block in detail to see if wear or a broken piston damaged the cylinder wall. As I already mentioned, the machine is unfortunately 200 kilometers away from me, so I rarely have the opportunity to repair it. Now I'm working on getting the parts. What do you suggest? The engine may only be refurbished with original Caterpillar parts, or aftermarket parts are also suitable, which have a more favorable price. As far as I know, you can also find Freeday Parts here in Europe, where they sell aftermarket parts of adequate quality. What is your opinion and experience about this? One more professional question, does the Cat 3204 DI engine have replaceable cylinder liners or do the pistons run directly in the engine block? What does the "DI" mark at the end of the engine type number mean? Thank you in advance for your help.

OzDozer

Senior Member

Oh, that's expensive and bad - but it's identical to the problems I found in my 3204. The original Cat 2 ring pistons are weak. Use IPD aftermarket 3 ring pistons, they are superior to anything else.

The engine is "parent bore" - that is, it does not use cylinder liners. You will have to machine the bores to oversize.

You need to measure the wear in the cylinder bore and make a decision on the final overbore dimension. Pistons available are only 0.020" oversize and 0.040" oversize.

Make sure you have the pistons in hand before you carry out any oversize boring, as there are specific instructions in the box, for bore sizing and finish for the IPD pistons.

The Caterpillar parts are expensive and will be slow to be acquired. However, ensure you use genuine Cat "little end" (bronze) conrod bushings.

These will come from Cat Japan and are the ONLY conrod bushings to install. These bushings are the weak point of the engine (besides the original pistons!).

The cylinder head also has no valve guide inserts, the valve stem runs directly on the cast iron head metal. These wear badly, and you will find the valve stems are "sloppy".

Machine the head to take "K-line" bronze valve stem inserts, and this will fix the problem. The "K-Line" inserts are excellent U.S.-made aftermarket parts.

Also, install new valve springs, because these are cheap and important to replace. Aftermarket valve springs are manufactured by S.B. International in the U.S. or by TRW.

You would be well advised to replace all the valves as well, good quality U.S-made aftermarket valves are easily obtained, and only cost around US$150 for a full set of 8 valves.

Friday Parts are an agent for Chinese-manufactured parts and components, and they are based in Hong Kong. I would not use Chinese internal engine parts or components, their quality is still not good enough.

I did purchase a Chinese water pump from Jeenda Controls, another seller of Chinese parts based in Hong Kong.

The water pump was cheap, and the quality is O.K., and if the water pump breaks down, it's not such a problem to replace - unlike a broken piston!

The "DI" means your engine uses Direct Injection in the combustion chamber. Earlier 3204's used "PC" - precombustion chambers, and the precombustion chamber design was a completely different design to DI.

Your bearings shows signs of what is called "cavitation erosion". This odd wear pattern can be caused by the oil pump sucking air, or inadequate oil pressure.

Make sure your oil pump rotors are in good condition, or replaced if they show wear. The oil pump rotor is very expensive to buy, about US$700 even for aftermarket. Cat want over US$1000 for their oil pump rotor.

I am re-using my oil pump rotor, because the rotor wear is minimal, and the wear level is still well within specification levels.

www.waukbearing.com

www.waukbearing.com

The engine is "parent bore" - that is, it does not use cylinder liners. You will have to machine the bores to oversize.

You need to measure the wear in the cylinder bore and make a decision on the final overbore dimension. Pistons available are only 0.020" oversize and 0.040" oversize.

Make sure you have the pistons in hand before you carry out any oversize boring, as there are specific instructions in the box, for bore sizing and finish for the IPD pistons.

The Caterpillar parts are expensive and will be slow to be acquired. However, ensure you use genuine Cat "little end" (bronze) conrod bushings.

These will come from Cat Japan and are the ONLY conrod bushings to install. These bushings are the weak point of the engine (besides the original pistons!).

The cylinder head also has no valve guide inserts, the valve stem runs directly on the cast iron head metal. These wear badly, and you will find the valve stems are "sloppy".

Machine the head to take "K-line" bronze valve stem inserts, and this will fix the problem. The "K-Line" inserts are excellent U.S.-made aftermarket parts.

Also, install new valve springs, because these are cheap and important to replace. Aftermarket valve springs are manufactured by S.B. International in the U.S. or by TRW.

You would be well advised to replace all the valves as well, good quality U.S-made aftermarket valves are easily obtained, and only cost around US$150 for a full set of 8 valves.

Friday Parts are an agent for Chinese-manufactured parts and components, and they are based in Hong Kong. I would not use Chinese internal engine parts or components, their quality is still not good enough.

I did purchase a Chinese water pump from Jeenda Controls, another seller of Chinese parts based in Hong Kong.

The water pump was cheap, and the quality is O.K., and if the water pump breaks down, it's not such a problem to replace - unlike a broken piston!

The "DI" means your engine uses Direct Injection in the combustion chamber. Earlier 3204's used "PC" - precombustion chambers, and the precombustion chamber design was a completely different design to DI.

Your bearings shows signs of what is called "cavitation erosion". This odd wear pattern can be caused by the oil pump sucking air, or inadequate oil pressure.

Make sure your oil pump rotors are in good condition, or replaced if they show wear. The oil pump rotor is very expensive to buy, about US$700 even for aftermarket. Cat want over US$1000 for their oil pump rotor.

I am re-using my oil pump rotor, because the rotor wear is minimal, and the wear level is still well within specification levels.

Bearing Damage: Cavitation Erosion

Cavitation erosion is an impact fatigue attack caused by the formation and collapse of vapor bubbles in the oil film under conditions of rapid pressure changes during the crank cycle in internal combustion engines.

Last edited:

thepumpguysc

Senior Member

- Joined

- Mar 18, 2010

- Messages

- 7,539

- Location

- Sunny South Carolina

- Occupation

- Master Inj.Pump rebuilder

Fantastic info OZDozer..!!!

mg2361

Senior Member

DittoFantastic info OZDozer..!!!

Oh, that's expensive and bad - but it's identical to the problems I found in my 3204. The original Cat 2 ring pistons are weak. Use IPD aftermarket 3 ring pistons, they are superior to anything else.

The engine is "parent bore" - that is, it does not use cylinder liners. You will have to machine the bores to oversize.

You need to measure the wear in the cylinder bore and make a decision on the final overbore dimension. Pistons available are only 0.020" oversize and 0.040" oversize.

Make sure you have the pistons in hand before you carry out any oversize boring, as there are specific instructions in the box, for bore sizing and finish for the IPD pistons.

The Caterpillar parts are expensive and will be slow to be acquired. However, ensure you use genuine Cat "little end" (bronze) conrod bushings.

These will come from Cat Japan and are the ONLY conrod bushings to install. These bushings are the weak point of the engine (besides the original pistons!).

The cylinder head also has no valve guide inserts, the valve stem runs directly on the cast iron head metal. These wear badly, and you will find the valve stems are "sloppy".

Machine the head to take "K-line" bronze valve stem inserts, and this will fix the problem. The "K-Line" inserts are excellent U.S.-made aftermarket parts.

Also, install new valve springs, because these are cheap and important to replace. Aftermarket valve springs are manufactured by S.B. International in the U.S. or by TRW.

You would be well advised to replace all the valves as well, good quality U.S-made aftermarket valves are easily obtained, and only cost around US$150 for a full set of 8 valves.

Friday Parts are an agent for Chinese-manufactured parts and components, and they are based in Hong Kong. I would not use Chinese internal engine parts or components, their quality is still not good enough.

I did purchase a Chinese water pump from Jeenda Controls, another seller of Chinese parts based in Hong Kong.

The water pump was cheap, and the quality is O.K., and if the water pump breaks down, it's not such a problem to replace - unlike a broken piston!

The "DI" means your engine uses Direct Injection in the combustion chamber. Earlier 3204's used "PC" - precombustion chambers, and the precombustion chamber design was a completely different design to DI.

Your bearings shows signs of what is called "cavitation erosion". This odd wear pattern can be caused by the oil pump sucking air, or inadequate oil pressure.

Make sure your oil pump rotors are in good condition, or replaced if they show wear. The oil pump rotor is very expensive to buy, about US$700 even for aftermarket. Cat want over US$1000 for their oil pump rotor.

I am re-using my oil pump rotor, because the rotor wear is minimal, and the wear level is still well within specification levels.

Bearing Damage: Cavitation Erosion

Cavitation erosion is an impact fatigue attack caused by the formation and collapse of vapor bubbles in the oil film under conditions of rapid pressure changes during the crank cycle in internal combustion engines.www.waukbearing.com

Hi OZDozer.

Thank you very much for the quick and comprehensive professional information!

For the "little end" bronze bushings, did you mean connecting rod bushings?

Maybe you can recommend a parts distributor where I can buy the complete replacement kit? - or is it more appropriate to buy them separately from the parts manufacturers listed above?

I have already consulted with a machine shop who will do the engine work and he also suggested that I take the engine there for inspection and then they will tell me what size parts I will need.

OzDozer

Senior Member

Yes, the connecting rod bushings that the piston pin rotates on. The Cat part number is 9N5082.

I cannot recommend a parts distributor who can supply the complete replacement kit, because you will then have no choice over the individual parts supplied.

The parts suppliers who supply complete kits, usually supply all Chinese parts.

I would suggest you find an IPD agent or distributor in your area and get them to supply as many U.S. made IPD components as they can supply.

Being in Hungary makes it difficult for me to make recommendations, as I'm not familiar with your countrys dealers or distributors.

It is good to take the engine to a machine shop who has a good record of repairing Cat engines. Many machine shops specialise in just a few makes, and become familiar with them.

It is important to have the repair/service manual for your tractor, so you can obtain the disassembly and assembly instructions and the specifications for clearances.

I cannot recommend a parts distributor who can supply the complete replacement kit, because you will then have no choice over the individual parts supplied.

The parts suppliers who supply complete kits, usually supply all Chinese parts.

I would suggest you find an IPD agent or distributor in your area and get them to supply as many U.S. made IPD components as they can supply.

Being in Hungary makes it difficult for me to make recommendations, as I'm not familiar with your countrys dealers or distributors.

It is good to take the engine to a machine shop who has a good record of repairing Cat engines. Many machine shops specialise in just a few makes, and become familiar with them.

It is important to have the repair/service manual for your tractor, so you can obtain the disassembly and assembly instructions and the specifications for clearances.

Nige

Senior Member

This is probably the single most important factor for a successful engine rebuild, or any repair on the machine for that matter.It is important to have the repair/service manual for your tractor, so you can obtain the disassembly and assembly instructions and the specifications for clearances.

You require Caterpillar Publication reference SENR2033. I took a quick look around and could not find anything used for sale.

Bearing in mind your location the cost of shipping a heavy paper manual (most likely from the USA) is probably uneconomic. All is not lost though, you can buy the manual in CD form from HERE for US$355.

The same source also has a Parts Manual (SEBP1456 for all 19Z-prefix machines with S/N above 253) on CD for US$109. I would say that the Service Manual is absolutely essential for what you propose to do, and the Parts Manual would be a close second on the list. If you have a Parts Manual you could search for eny part you require using the Cat OEM Part Number which would give you access to both Cat & aftermarket parts

Dear Nige,

I was expecting your application.

As I mentioned above, I already acquired the original documentation for the machine. My parts catalog is slightly different, but still usable.

Thank you for your attention and help.

Could you help me with the purchase of spare parts? A specific parts distributor, or even personal contact?

I already wrote to the companies specified by OzDozer on Friday, but I haven't received a response yet. It's true, it was the weekend, maybe I'm a little impatient?!

I wish you a nice day.

I was expecting your application.

As I mentioned above, I already acquired the original documentation for the machine. My parts catalog is slightly different, but still usable.

Thank you for your attention and help.

Could you help me with the purchase of spare parts? A specific parts distributor, or even personal contact?

I already wrote to the companies specified by OzDozer on Friday, but I haven't received a response yet. It's true, it was the weekend, maybe I'm a little impatient?!

I wish you a nice day.

Attachments

OzDozer

Senior Member

cat951b, here is the IPD website link (below) with a range of literature to inform you. There is an IPD Headquarters for European parts distribution, they will be able to advise you who your local IPD distributor or agent is, in Hungary.

It appears IPD EU operate from Poland, the manager is listed as Michal Owczarek, and he can be contacted at mowczarek@ipdparts.com - or call him at +45 7550 7666.

www.ipdparts.com

www.ipdparts.com

www.ipdparts.com

www.ipdparts.com

It appears IPD EU operate from Poland, the manager is listed as Michal Owczarek, and he can be contacted at mowczarek@ipdparts.com - or call him at +45 7550 7666.

Literature - Premium Quality Heavy-Duty Engine Parts

IPD shares resources on a wide range of engine related topics, including parts, industries and applications. Download the brochures from our website.

www.ipdparts.com

www.ipdparts.com

Landing Page - Europe - Premium Quality Heavy-Duty Engine Parts

Explore top-tier engine parts at IPD Europe. Elevate your vehicle's performance and reliability with our premium components. Shop now for excellence!

www.ipdparts.com

www.ipdparts.com

Nige

Senior Member

Sorry I have no leads regarding the availability of spare parts other than the ones already mentioned.Could you help me with the purchase of spare parts?

Hi OzDozer,cat951b, here is the IPD website link (below) with a range of literature to inform you. There is an IPD Headquarters for European parts distribution, they will be able to advise you who your local IPD distributor or agent is, in Hungary.

It appears IPD EU operate from Poland, the manager is listed as Michal Owczarek, and he can be contacted at mowczarek@ipdparts.com - or call him at +45 7550 7666.

Literature - Premium Quality Heavy-Duty Engine Parts

IPD shares resources on a wide range of engine related topics, including parts, industries and applications. Download the brochures from our website.www.ipdparts.com

Landing Page - Europe - Premium Quality Heavy-Duty Engine Parts

Explore top-tier engine parts at IPD Europe. Elevate your vehicle's performance and reliability with our premium components. Shop now for excellence!www.ipdparts.com

great info again! Thank you and I appreciate it.

I haven't found it yet.

I am already writing to Mr. Owczarek..

If there is progress I will apply.

Good day everyone!

Greetings to everyone!

Little by little, things are changing.

The engine is in the machine shop, the parts are ordered with Ozdozer's recommendation from IPD.

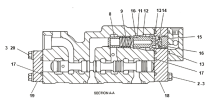

I would also like to replace the seals of the hydrostat that can be "externally" reached, but I have already found 2 anomalies (see the photos), the Teflon seals of both pistons were pinched!! (In my opinion, this is still the original factory-installed Hydrostat) Could this have caused the problem?

The O-rings are not visibly damaged, nor are the pistons clearly worn on one side.

What would be important: I would need these O-rings and support (Teflon) rings for the part.

I couldn't find it in the Parts book. But maybe I was just careless?!

Little by little, things are changing.

The engine is in the machine shop, the parts are ordered with Ozdozer's recommendation from IPD.

I would also like to replace the seals of the hydrostat that can be "externally" reached, but I have already found 2 anomalies (see the photos), the Teflon seals of both pistons were pinched!! (In my opinion, this is still the original factory-installed Hydrostat) Could this have caused the problem?

The O-rings are not visibly damaged, nor are the pistons clearly worn on one side.

What would be important: I would need these O-rings and support (Teflon) rings for the part.

I couldn't find it in the Parts book. But maybe I was just careless?!

Attachments

Nige

Senior Member

Maybe not “damaged” as you think but it is obvious from the photos that the O-Rings are no longer circular in cross-section. They appear to be almost square and I would bet that their material is very hard. It is quite likely that they were leaking.The O-rings are not visibly damaged

The Teflon ring is usually called a “Ring - Backup” in Cat parts manuals.

Nige

Senior Member

Nige

Senior Member

Actually there is damage on at least one O-Ring when the photo is zoomed. See below.The O-rings are not visibly damaged

I also think that I know why the Teflon backup rings have worn, and it all revolves around the fact that the O-Rings were originally a circular cross-section when they were new but now they appear to be almost square.

The material of the 4J-8996 Seal material when new is 3.53mm in diameter - shown by the black circle.

If the seal is flattened over time until the cross section transforms from that circle to effectively a square with rounded corners then the "height" of the seal in the groove reduces to approximately 2.9mm - shown by the red square.

This is what I think has caused the load to move from the seal to the Teflon backup ring and caused the wear to said ring.