Apologies for posting on another forum already.

Any help would be appreciated. I have a 303.5 with less than 2000 hours on it. It has never had any issues in the past. It has not been used seriously in 10 years but it has been moved around the garden and used to do maybe 20 minutes of scraping at a time every few months.

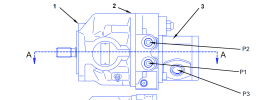

It was moved into a new position in November. Last week I went to move it and she started first go as usual but none of the hydraulics are working.

The drop down safety switch seems to be working as the ignition will not work with it down.

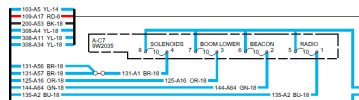

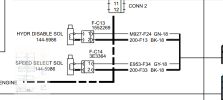

I suspect it is some sensor or electrical issue, fuses are all ok. I do not have a repair manual or electrical layout.

Machine is stuck in my back yard locking in a car that I want to use.

Can anyone suggest where I might start looking for an issue.

Quote Reply

Any help would be appreciated. I have a 303.5 with less than 2000 hours on it. It has never had any issues in the past. It has not been used seriously in 10 years but it has been moved around the garden and used to do maybe 20 minutes of scraping at a time every few months.

It was moved into a new position in November. Last week I went to move it and she started first go as usual but none of the hydraulics are working.

The drop down safety switch seems to be working as the ignition will not work with it down.

I suspect it is some sensor or electrical issue, fuses are all ok. I do not have a repair manual or electrical layout.

Machine is stuck in my back yard locking in a car that I want to use.

Can anyone suggest where I might start looking for an issue.

Quote Reply