RenoHuskerDu

Senior Member

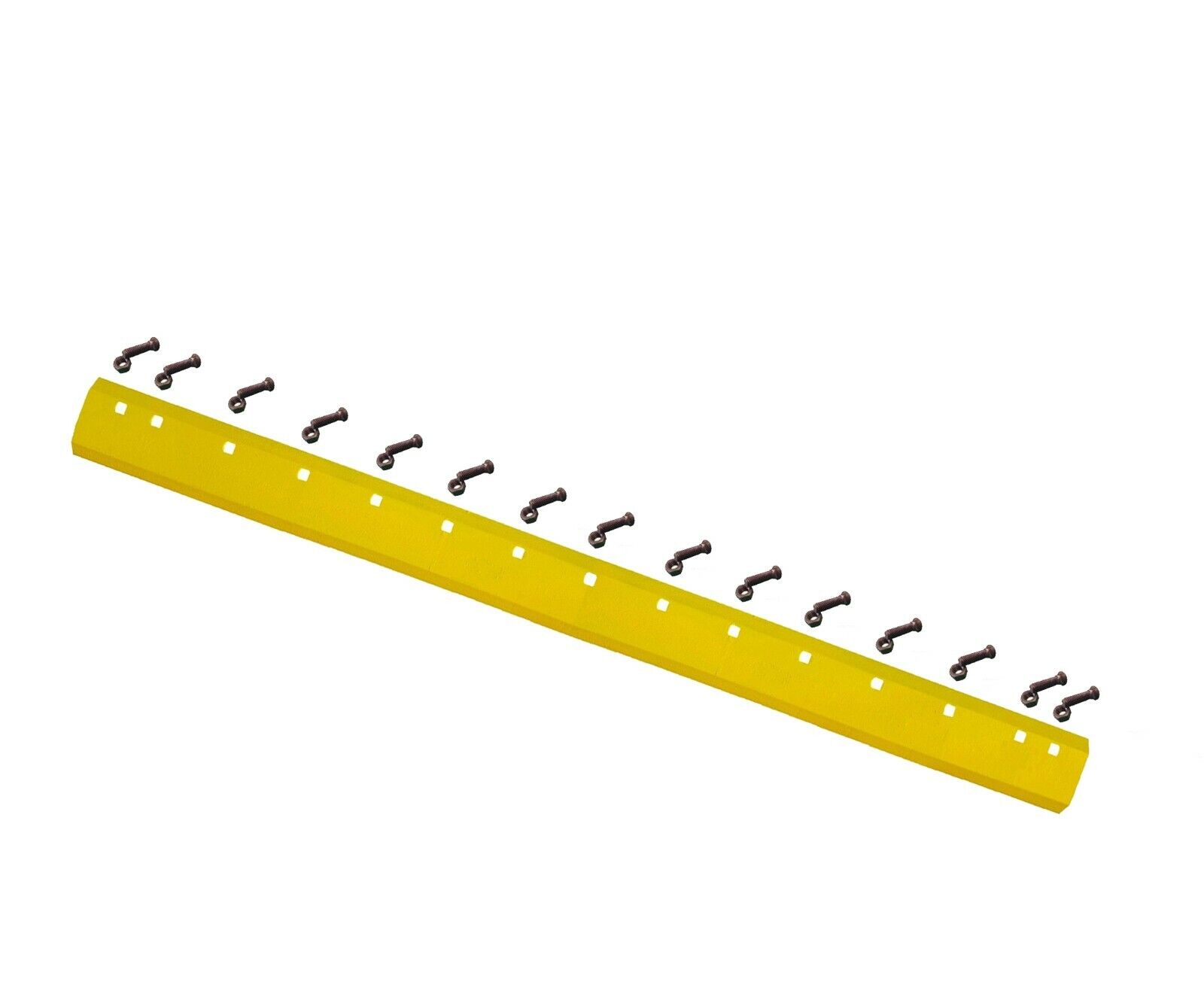

My Mauldin M413XT has a 7' wide bucket. I want to extend the forward edge to increase volume capacity. I priced a piece of abrasion-resistant steel and it would be $650. Even my welder/steel guy said that's too high. We both thought that I could find one for sale to weld on and pay less. I bought one for an LS tractor a couple years ago and it was $200. But tractor buckets are typically a bit narrower.

Anybody know a source for bucket lips?

Anybody know a source for bucket lips?