Fourtencustoms

Well-Known Member

Hello from North Idaho!

I bought a 1998 Takeuchi TB035 mini excavator that needs some work.

The machine itself is in very good condition, but it has high hours.

I got a very good deal on it, this is for personal use around our property digging drainage, ditches, ponds, maintaining our road, etc.

I purposely bought a machine that needs work in an effort to save some money, this machine was $14000 and in our market this is $10K lower then comparable machines. I have done my home work and realize how great the Takeuchi machines are.

I build custom Ford Rangers, Explorers and diesel trucks. I am a moderator over at Explorerforum.com and you can also find me on Polaris forums, atv forums, snowmobile forums and powerstroke forums under the name 410Fortune / 410customs

There are two MAIN area's on this machine that need fixing, the instrument cluster, right hand console wiring and the Yanmar engine.

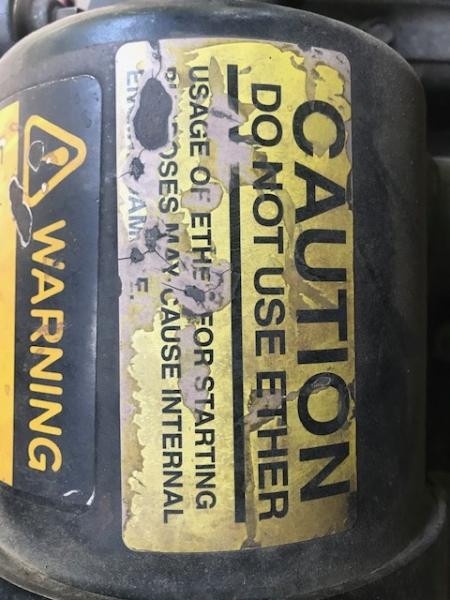

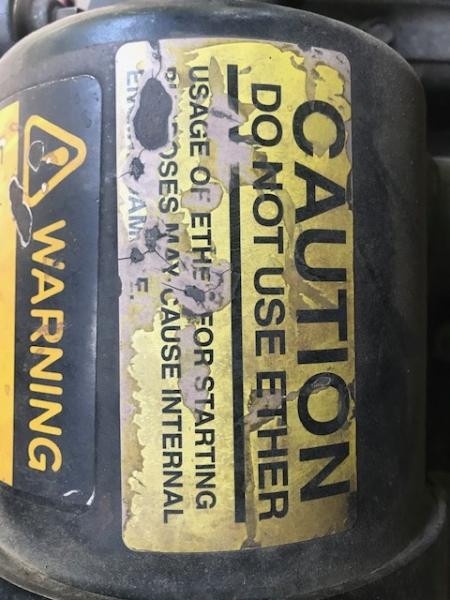

The engine is tired, it has been started with ether for who knows how many years now. Basically it will not start without the ether and when it does run and gets warm then under load it will die and not re start.

I am currently looking into repower options, I have about $5-10K to "play" with

At first I was thinking no big deal just buy a whole new/reman engine and drop it in. Well there is no such thing as a reman 3TN84TL-RTBY it is too old.

Yanmar can sell me a short block for over $3600 with 120 day lead time, no thanks!

Now I am looking at either replacing it with a different engine or rebuilding this engine/injection pump/turbo myself

I am currently fixing the wiring and hope to resurrect the original instrument cluster, if not I will add my own gauges and warning lights, switches, should not be a problem.

I specialize in wiring/electrical, but I also know my way around 2 stroke, 4 stroke and diesel engines everything from 49cc to 7300cc

I have not done a compression or leak down test yet

I know it is getting fuel and the air filter/intake are clean

the turbo has oil leaks on both sides, in and out

When it does start it seems to be running on all 3 cylinders and runs pretty well (though it does seem doggy)

Many other small oil and coolant leaks

Small fluid leak between the engine and the pump

Symptoms:

only starts with ether unless its already warm

Once warm and put under load it will die, and 85% of the time will not re start

Everything else on the machine works as it should and is actually in very good shape, no major hydraulic leaks, tracks are nice, a little bit of looseness in the bucket pins, otherwise I am very happy with this purchase.

So I am researching how to do the compression test, I have a diesel compression tester and I see Hoye tractor sells a Yanmar injector adapter for $23

I know diesels enough to know this sucker needs rebuild, it has plenty of blow by and is very low in power (33hp feels more like 15)

Both cold start aids have been broken for who knows how long, it has a thermostart I believe and an intake heater. The big orange wires that feed these are in bad shape and have been left unhooked.

The machine has a can of ether sitting in a metal holder that looks like it was added to hold the ether. So this diesel has been abused!!

Whats next? Pull the yanmar, order a rebuild kit and get to work? or more troubleshooting?

I know I can tear down the block and rebuild it with new bearings, sleeves, pistons. I will likely need to take the head to a local machine shop to have rebuilt. I can order a new turbo or rebuild it myself?

Thanks fellas, we would like to get this thing up and running asap

I know I have alot of questions, a few days of researching this machine and engine has lead me here

HELP!!!

Thank you in advance

I bought a 1998 Takeuchi TB035 mini excavator that needs some work.

The machine itself is in very good condition, but it has high hours.

I got a very good deal on it, this is for personal use around our property digging drainage, ditches, ponds, maintaining our road, etc.

I purposely bought a machine that needs work in an effort to save some money, this machine was $14000 and in our market this is $10K lower then comparable machines. I have done my home work and realize how great the Takeuchi machines are.

I build custom Ford Rangers, Explorers and diesel trucks. I am a moderator over at Explorerforum.com and you can also find me on Polaris forums, atv forums, snowmobile forums and powerstroke forums under the name 410Fortune / 410customs

There are two MAIN area's on this machine that need fixing, the instrument cluster, right hand console wiring and the Yanmar engine.

The engine is tired, it has been started with ether for who knows how many years now. Basically it will not start without the ether and when it does run and gets warm then under load it will die and not re start.

I am currently looking into repower options, I have about $5-10K to "play" with

At first I was thinking no big deal just buy a whole new/reman engine and drop it in. Well there is no such thing as a reman 3TN84TL-RTBY it is too old.

Yanmar can sell me a short block for over $3600 with 120 day lead time, no thanks!

Now I am looking at either replacing it with a different engine or rebuilding this engine/injection pump/turbo myself

I am currently fixing the wiring and hope to resurrect the original instrument cluster, if not I will add my own gauges and warning lights, switches, should not be a problem.

I specialize in wiring/electrical, but I also know my way around 2 stroke, 4 stroke and diesel engines everything from 49cc to 7300cc

I have not done a compression or leak down test yet

I know it is getting fuel and the air filter/intake are clean

the turbo has oil leaks on both sides, in and out

When it does start it seems to be running on all 3 cylinders and runs pretty well (though it does seem doggy)

Many other small oil and coolant leaks

Small fluid leak between the engine and the pump

Symptoms:

only starts with ether unless its already warm

Once warm and put under load it will die, and 85% of the time will not re start

Everything else on the machine works as it should and is actually in very good shape, no major hydraulic leaks, tracks are nice, a little bit of looseness in the bucket pins, otherwise I am very happy with this purchase.

So I am researching how to do the compression test, I have a diesel compression tester and I see Hoye tractor sells a Yanmar injector adapter for $23

I know diesels enough to know this sucker needs rebuild, it has plenty of blow by and is very low in power (33hp feels more like 15)

Both cold start aids have been broken for who knows how long, it has a thermostart I believe and an intake heater. The big orange wires that feed these are in bad shape and have been left unhooked.

The machine has a can of ether sitting in a metal holder that looks like it was added to hold the ether. So this diesel has been abused!!

Whats next? Pull the yanmar, order a rebuild kit and get to work? or more troubleshooting?

I know I can tear down the block and rebuild it with new bearings, sleeves, pistons. I will likely need to take the head to a local machine shop to have rebuilt. I can order a new turbo or rebuild it myself?

Thanks fellas, we would like to get this thing up and running asap

I know I have alot of questions, a few days of researching this machine and engine has lead me here

HELP!!!

Thank you in advance

Last edited: