dave.zap

New Member

Hi, I'm new to the forum.

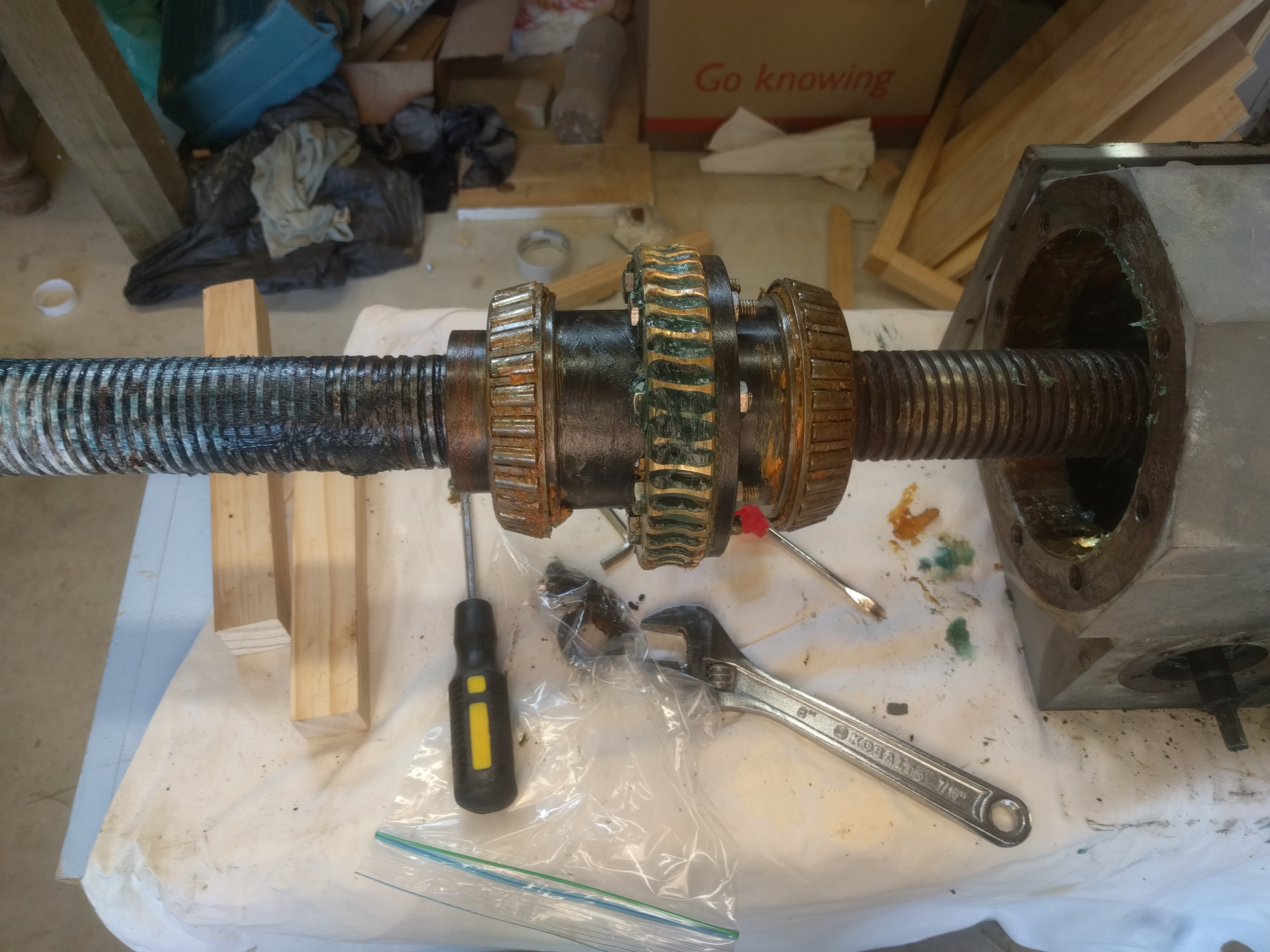

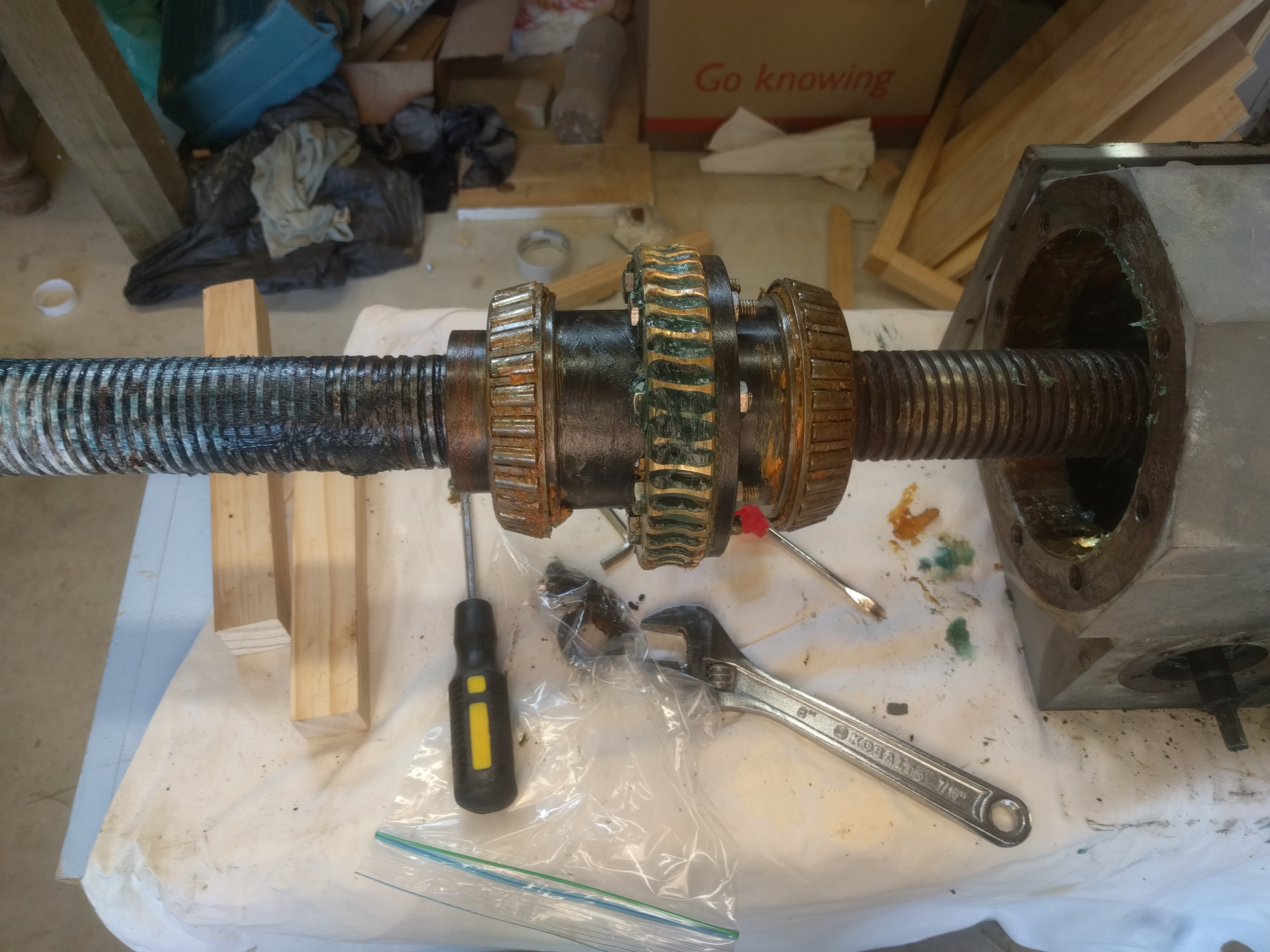

Pictures below are of a linear actuator from a large satellite dish - hence posting this in this group I'm not sure where it should go.

It is driven by an electric motor that I've removed. The gear housing is the large box on the right and the threaded shaft is canvas cover on the business end but not the back end. It's here I think perhaps dirt has entered? But what ever the case it will not in and out when I manually turn the drive. It has been sitting in place (outside) without being serviced or used for about 10 years.

So I've pulled it apart and found that the main 'screw' thingy (I'm going to struggle with the correct names for things here) is frozen to the main shaft. This is shown in the second picture.

I've sprayed a lot of CRC into both ends but I can't make it budge.. No idea if the thread on the inside is damage or if it's just crime or what's going on. But I would really like to fix this.. what are my chances please help. All advice is welcome.

I'm in LOCKDOWN in New Zealand !!!

Pictures below are of a linear actuator from a large satellite dish - hence posting this in this group I'm not sure where it should go.

It is driven by an electric motor that I've removed. The gear housing is the large box on the right and the threaded shaft is canvas cover on the business end but not the back end. It's here I think perhaps dirt has entered? But what ever the case it will not in and out when I manually turn the drive. It has been sitting in place (outside) without being serviced or used for about 10 years.

So I've pulled it apart and found that the main 'screw' thingy (I'm going to struggle with the correct names for things here) is frozen to the main shaft. This is shown in the second picture.

I've sprayed a lot of CRC into both ends but I can't make it budge.. No idea if the thread on the inside is damage or if it's just crime or what's going on. But I would really like to fix this.. what are my chances please help. All advice is welcome.

I'm in LOCKDOWN in New Zealand !!!