ROAMER_AUS

Well-Known Member

Hi all,

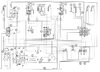

I have this configuration of slew motor on Terex mini excavator. Upon activation of the command, my pilot pressure drops from nominal 25 bar to 5-10 bar and it is very slow and powerless in rotation. I have checked everything else, and it is good. My only suspect are these two non return valves. Connection is marked T but it is connected to pilot hydraulics. Maunal states that pressure on return line of the motor should be 30 bar, which is more than 25 and no loss of pressure there. But somehow I'm still loosing it. Does anybody know what are these two valves for?

Thanks.

I have this configuration of slew motor on Terex mini excavator. Upon activation of the command, my pilot pressure drops from nominal 25 bar to 5-10 bar and it is very slow and powerless in rotation. I have checked everything else, and it is good. My only suspect are these two non return valves. Connection is marked T but it is connected to pilot hydraulics. Maunal states that pressure on return line of the motor should be 30 bar, which is more than 25 and no loss of pressure there. But somehow I'm still loosing it. Does anybody know what are these two valves for?

Thanks.