T_Gunn

Active Member

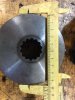

So I removed the pump assembly on my 1991 Linkbelt LS2700C2 to have some hydraulic leaks fixed. When I remove the pump housing it was immediately obvious what had been clunking every time I shut the machine off. (see picture of engine drive plate and coupler 'fingers') After a great deal of internet research and calls to my Linkbelt and Case dealers (this Linkbelt is also a Case 9020 with a Cummins 4bt instead of an Isuzu 4BD1T) I learned that parts are getting very difficult to get for my 25 year old machine. So long story short, I ended up buying a new pump coupler on Ebay, which is advertised as being for a JCB JS150 machine, which I learned is a UK version of the same machine. The part no's for the coupler are the same. After receiving the JCB coupler, and starting to install it, I now realize that it is a bit of a generic piece that fits a lot of excavators. If you look at my picture of the coupler, you can see that the bore holes that bolt to the drive plate/flywheel size on the engine side of the coupler are machined through holes of the same size. The head of the allen head bolts that bolts the coupler to the engine plate is smaller than the bore hole so that the bolt head will sit below the surface of the coupler when installed. But...there is no step in the bolt hole to tighten the bolt and coupler to the drive plate. When I looked more closely at the original worn out drive 'finger', it appears that there is a bushing pressed into the finger (see picture). This bushing would be what the allen bolt tightens on to clamp the coupler to the drive plate. So...I tried to press this bushing out of the finger with a 6 ton jack and it won't budge. My question is... is this actually a bushing that can be pressed out, I just need more than 6 tons of force? Would I be better off to source a new set of bushings that need to be installed in the new coupler piece? Is a press fitted bushing going to be enough to keep the coupler from moving away from the drive plate over time?, as it will be the only thing actually holding the coupler against the drive plate?

Hope I am making sense. Any help would be welcome.

Hope I am making sense. Any help would be welcome.