pkw

Member

Hi all, I got a new to me D6c dozer last fall. Ran her all winter clearing brush and pushed in a few roads with no problems. Now that its Summer She is getting hot. I am doing some hard ripping and pushing dozing in a building pad. I was wondering what is the proper operating temp for this machine?

details:

D6c 10k8472

temp reaches 218f +/- and holds dosent boil over as far as i can tell

checked radiator tank temp with infrared- matched gauge reading

new radiator

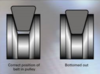

checked fan blades- in correct pusher position

powershift not getting hot- stays far from the "red" zone on gauge

when warm and put into high idle and neutral she cools down to 190F within a minute or two another minute shes at 185ish

took brush engine guards off- made little to no difference

new belt- checked tension good

3500 elevation

ambient outside temp 100f

Is 218F a okay operating temp or should I be concerned?

details:

D6c 10k8472

temp reaches 218f +/- and holds dosent boil over as far as i can tell

checked radiator tank temp with infrared- matched gauge reading

new radiator

checked fan blades- in correct pusher position

powershift not getting hot- stays far from the "red" zone on gauge

when warm and put into high idle and neutral she cools down to 190F within a minute or two another minute shes at 185ish

took brush engine guards off- made little to no difference

new belt- checked tension good

3500 elevation

ambient outside temp 100f

Is 218F a okay operating temp or should I be concerned?