BrianGrenier

Senior Member

Oil filter on a 1999 Cat320BL s/n 9js00 (made in JP and imported to US from CA), 3066 engine blew it's gasket.

Another time before, I don't recall if the gasket blew, or the filter worked itself loose, but both times made a mess.

Lots of hours on the meter. Engine runs well with no lifter noise or knocks.

The filter(s) wasn't overtightened or under, as far as I know.

Looking on the web it seems that high pressure would be a possibility. I had purchased a mechanical gauge that I had meant to install but haven't gotten around to it. The oil is dirty and I also planned to change the oil and have the new filter in the cab. Before the last oil change a Blackstone lab oil report said the wear of the oil was high and it didn't look like the oil was changed recently. There are not a lot of hours on the current oil but it looks dirty.

Oil light has been on and off. There is no oil pressure gauge. Thankfully there was a honk from something on the engine when it spewed oil.

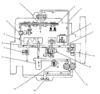

So that's the background. What I'm looking for today is the location of the oil pressure sender, how to test and suggestions for what I might look for to keep this from happening again.;-)

Another time before, I don't recall if the gasket blew, or the filter worked itself loose, but both times made a mess.

Lots of hours on the meter. Engine runs well with no lifter noise or knocks.

The filter(s) wasn't overtightened or under, as far as I know.

Looking on the web it seems that high pressure would be a possibility. I had purchased a mechanical gauge that I had meant to install but haven't gotten around to it. The oil is dirty and I also planned to change the oil and have the new filter in the cab. Before the last oil change a Blackstone lab oil report said the wear of the oil was high and it didn't look like the oil was changed recently. There are not a lot of hours on the current oil but it looks dirty.

Oil light has been on and off. There is no oil pressure gauge. Thankfully there was a honk from something on the engine when it spewed oil.

So that's the background. What I'm looking for today is the location of the oil pressure sender, how to test and suggestions for what I might look for to keep this from happening again.;-)