ben46a

Senior Member

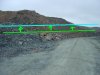

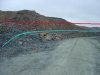

So our 385C operator gave his notice, so there going to try me out on it. Its primary job is loading out shotrock from the face. Ive never Ran a production machine to this effect. I understand that about a 10-12 ft bench will be the best for loading off, but with a 50 ft face, hows the best way to go about this? I already geared up and built a bench. But should i just load out of the face behind the machoine and form a new bench, then dig out the one im on, or what. Any help will be greatly appreciated.