-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My first track loader!

- Thread starter boone

- Start date

Adjuster Disassembly

We've been nursing the left track for quite a while. It's been requiring more and more frequent tightening. After the last dirt job we did, we tried to tighten it again and the track never moved. Looked under the track cylinder - big glob of grease coming out...

We learned a lot doing this. We made some mistakes and so this representation is not the most ideal. One of our first issues was the combination of getting the split link over the idler, in the shade, on a level spot. Being in the shade was top priority. We were 2 for 3. Unfortunately, just as we broke the track, we realized we weren't on a very level spot. It is what it is...

We are super lucky this machine has a split link. Figured the toughest part would be getting the track bolts loose. They actually broke loose fairly easy with a 3/4" pull handle and 4' pipe (not the one pictured). The only casualty was a cheap chinese socket that split. I should've known better. The 6 point impact socket worked much better.

After the pad bolts were removed, we stood back and tapped the link with the shop hammer couple of times and the track flopped down.

Early in the morning. We parked this thing between two big oak trees. The sunlight was really coming through. Dad is 75 and can still outwork me.

Removed the 4 bolts holding the front idler plates. Just after this, we lifted the front to get the weight off the idler.

We've been nursing the left track for quite a while. It's been requiring more and more frequent tightening. After the last dirt job we did, we tried to tighten it again and the track never moved. Looked under the track cylinder - big glob of grease coming out...

We learned a lot doing this. We made some mistakes and so this representation is not the most ideal. One of our first issues was the combination of getting the split link over the idler, in the shade, on a level spot. Being in the shade was top priority. We were 2 for 3. Unfortunately, just as we broke the track, we realized we weren't on a very level spot. It is what it is...

We are super lucky this machine has a split link. Figured the toughest part would be getting the track bolts loose. They actually broke loose fairly easy with a 3/4" pull handle and 4' pipe (not the one pictured). The only casualty was a cheap chinese socket that split. I should've known better. The 6 point impact socket worked much better.

After the pad bolts were removed, we stood back and tapped the link with the shop hammer couple of times and the track flopped down.

Early in the morning. We parked this thing between two big oak trees. The sunlight was really coming through. Dad is 75 and can still outwork me.

Removed the 4 bolts holding the front idler plates. Just after this, we lifted the front to get the weight off the idler.

We put a C-clamp on the idler wheel and chained it to the back of my UTV. Pulled right out. The yoke and rod.

The rod was smoother than it looked, but we're going to buff it anyway and knock some of the paint back.

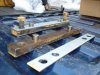

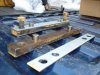

Removed the grease zerk (bottom left) and the check valve (bottom right). Then used a 1/2" threaded rod to pull the piston out.

The rod was smoother than it looked, but we're going to buff it anyway and knock some of the paint back.

Removed the grease zerk (bottom left) and the check valve (bottom right). Then used a 1/2" threaded rod to pull the piston out.

I ordered a sealkit from Baum, PN 906003 for $69.30. It wasn't the cheapest I found online, but we had good luck on the tilts and brake booster cylinder kits from them.

To get the yoke unbolted we man handled the idler back up into the carrer with the yoke turned to the front. This braced the assembly enough for us to extract the four bolts holding the yoke.

This week we'll get everything ready for assembly - put the seals on the piston, clean and hone the barrel, buff the rod in the shop. This honing pic was just for demo purposes

Assembly will hopefully happen next Saturday.

To get the yoke unbolted we man handled the idler back up into the carrer with the yoke turned to the front. This braced the assembly enough for us to extract the four bolts holding the yoke.

This week we'll get everything ready for assembly - put the seals on the piston, clean and hone the barrel, buff the rod in the shop. This honing pic was just for demo purposes

Assembly will hopefully happen next Saturday.

Last edited:

DMiller

Senior Member

Remember to soak the fiber rings in some form of light oil prior to install, use a hose clamp and bit of flat tin to compress them back down.

We'll be sure to lube up the seals. The manual also says to put a thin film of grease on the walls of the cylinder and piston. In addition to a small glob of grease into the cylinder before inserting the adjusting rod.

One thing we noticed while we were disassembling the yoke from the idler wheel was the thin rail on top of the guide blocks were incredibly worn. I didn't take a picture but they have a lot of play. Spec is .062" max clearance. Ours were about .25"+. PN is 655 805 C1. I called our local Komatsu dealer to see if they were available? Surprisingly they are. I can buy the pair from the dealer for $890 which the parts guy said was a good deal considering the list price on just one was $733. I also found a pair of gold bars...I mean guide blocks on ebay for $1000. lol

I also found a pair of gold bars...I mean guide blocks on ebay for $1000. lol

One thing we noticed while we were disassembling the yoke from the idler wheel was the thin rail on top of the guide blocks were incredibly worn. I didn't take a picture but they have a lot of play. Spec is .062" max clearance. Ours were about .25"+. PN is 655 805 C1. I called our local Komatsu dealer to see if they were available? Surprisingly they are. I can buy the pair from the dealer for $890 which the parts guy said was a good deal considering the list price on just one was $733.

Last edited:

kshansen

Senior Member

- Joined

- Mar 11, 2012

- Messages

- 11,160

- Location

- Central New York, USA

- Occupation

- Retired Mechanic in Stone Quarry

One thing we noticed while we were disassembling the yoke from the idler wheel was the thin rail on top of the guide blocks were incredibly worn. I didn't take a picture but they have a lot of play. Spec is .062" max clearance. Ours were about .25"+. PN is 655 805 C1. I called our local Komatsu dealer to see if they were available? Surprisingly they are. I can buy the pair from the dealer for $890 which the parts guy said was a good deal considering the list price on just one was $733.I also found a pair of gold bars...I mean guide blocks on ebay for $1000. lol

Not familiar with those parts but they look pretty simple design. How about running a couple good passes with a welder then either grind them to new spec's or have a machine shop pop them in a Bridgeport and machine them to the correct size? For the prices you are getting quoted a guy could enroll in a night school class at local tech school and make a couple of those parts as a school project and be money ahead! Or even go to the school and talk to instructor and see if there is a kid looking for a project and offer him some bucks!

They do look fairly simple. No kidding on the money going toward tuition! And this is just for one side. I'm sure the other side is just as worn. Although now that I look at the picture, I feel a little better. The top lip doesn't go all the way to the end like the bottom. I thought ours had worn the lip completely off for a quarter of the length. If we were just starting out with it, we might mess with it, but we'll probably just shove it back in.

kshansen

Senior Member

- Joined

- Mar 11, 2012

- Messages

- 11,160

- Location

- Central New York, USA

- Occupation

- Retired Mechanic in Stone Quarry

They do look fairly simple. No kidding on the money going toward tuition! And this is just for one side. I'm sure the other side is just as worn. Although now that I look at the picture, I feel a little better. The top lip doesn't go all the way to the end like the bottom. I thought ours had worn the lip completely off for a quarter of the length. If we were just starting out with it, we might mess with it, but we'll probably just shove it back in.

While you have them out at least do some measuring and make up a drawing so that if you just happen to find someone who has access to some basic machine tools they could make them for you.

I think the only thing that would need rebuilding would be the lip on the top of the block. Probably like you mentioned have it welded up and machined to spec. I'll take some measurements like you said. Wonder what a ballpark estimate would be to get these made at a typical machine shop?

DMiller

Senior Member

Is amazing how well 7018 edge dressed with a mill will wear!!

We ended up not welding and machining the lip on the guide block, but we did add a shim on the idler guide and wear bar. You can order these, but we just used a piece of bar stock from TSC and drilled a couple of holes for the dowels and bolts. This wear bar could also easily be made. We took measurements of it in case we ever need them.

The wear bars at the bottom are welded and were only lightly worn. The top gets the wear. These bolt to the upper side of the frame. Once unbolted, IH was smart enough to put a hole in the frame that goes all the way through so a punch can be used to knock them out. It's stuff like this that makes this machine a pleasure to work on.

Idler in and all the way back. You can see the upper and lower guide bars the guide block rides on. On the cribbing :nono I'll just say we both forgot about bringing any. I wouldn't use anything less than 6x6. FWIW, it's been up for a week like this.

This got us a little closer to spec.

The wear bars at the bottom are welded and were only lightly worn. The top gets the wear. These bolt to the upper side of the frame. Once unbolted, IH was smart enough to put a hole in the frame that goes all the way through so a punch can be used to knock them out. It's stuff like this that makes this machine a pleasure to work on.

Idler in and all the way back. You can see the upper and lower guide bars the guide block rides on. On the cribbing :nono I'll just say we both forgot about bringing any. I wouldn't use anything less than 6x6. FWIW, it's been up for a week like this.

This got us a little closer to spec.

Hi Boone. After reading Nitelite's lengthy thread I had to read yours! Both threads are inspiring. I will, hopefully, be doing some very similar clean-up and clearing at our place over the next few years--your before and after photos are quite compelling and make me hopeful that we can reclaim more of the old homestead. Unfortunately, we can't bury rocks here--we grow them quite well!

Your photos of the small sinkhole are quite interesting--when you can see water flowing from one side to another like that we call it a "karst window". I can't recall that I've ever seen one completely in dirt! Usually they are in bedrock (at least the ****** portion). Is it located near to and uphill from the spring? (feel free to respond via private message--I have some other questions as well).

I do hope that you and your family are well and awaiting the holidays with anticipation! At least I'm sure your junior operator is!

Your photos of the small sinkhole are quite interesting--when you can see water flowing from one side to another like that we call it a "karst window". I can't recall that I've ever seen one completely in dirt! Usually they are in bedrock (at least the ****** portion). Is it located near to and uphill from the spring? (feel free to respond via private message--I have some other questions as well).

I do hope that you and your family are well and awaiting the holidays with anticipation! At least I'm sure your junior operator is!

sealark37

Well-Known Member

- Joined

- Jun 3, 2012

- Messages

- 120

- Location

- Davidson, NC

- Occupation

- Retired pilot, old equipment mechanic

Hello Boone- I noticed some custom modifications to your tractor boom pole. Mine has received similar treatment. I bought it in two pieces from an overload, so some reinforcement was in order. I enjoy your posts, and I do admire your beautiful family farm. Keep up the good work. Regards, Clark

Hi Jim, I'm a bit jealous of your position in starting your clearing. I thoroughly enjoyed clearing our place off, would love to go back and do it again. I see your considering a dozer since you already have a JD 350 TL. You have more seat time than I and my experience is very limited to a TL. The TL is better than a dozer at some things, but not as good on others. If newbs like us can use a TL to do what we've done, they're pretty good choice for clearing. The 175 we've used has done everything we wanted. Everytime we used it for the day, we would always sing its praise amazed at what it could do. It really has been a good tool for the work we did. We've used the tractor and box blade to finish and cleanup, it's much cheaper to run rubber than tracks and leaves a cleaner footprint.

Our 175 fits in the existing barn perfectly, something a wider machine probably wouldn't do - I consider that free storage. Having said that I'd still love to have a TD-15C for the wider blade and traction, of course along with a 175 (like HEF member dhutch). I'm a bit jealous of these guys like Nitelite with big money that can have a loader, dozer and big green tonka truck too. LOL!

Loose rocks like to make their way around a narrow loader bucket. If I were looking at a dozer, I'd consider finding a cherry TD-15C. They're cheaper than Cats. Most C model parts can still be had and they're easy to work on. There is no denying Cat has them all beat on parts and resell, but they seem more difficult to work on and you a pay a premium because it's Cat. I'd still consider a D6D, then D6C. Couple of years ago we found a premium D6C for $32,500!! It had an impressive resume that I suppose justified the cost. New undercarriage and was sitting on a pile of dirt from a 2+ acre pond it had just built. For trackloader, probably a 953 or 955. Some of the JD 650's dozers with the six-ways would be nice too, but $$.

I had to google "karst window". The definition seems to describe it perfectly except the limestone wall part as you noted. But there is limestone on the place. We live in Limestone County. I should see if the sink hole has grown any. I haven't checked it since I took those pictures probably 3 year ago. It's on a hill base, but still uphill from a lower spring. The closest spring is probably 600' away. I'm itching to build a pond at that particular spring, but have reservations about whether the TL is right for the job. I'm afraid of getting it stuck with the weight and narrow pads. This fall would've been a perfect time. We had a bad drought. The spring was dryer than I've ever seen although it still had water.

Would be glad to answer any questions. I may be in and out on the net for a week or two. We just closed on a house and 14 acres and will be working to get the data line in next week. Lots of projects ahead of me. Gonna have to put my two little helpers to work.

Merry Christmas and Happy New Year to you and your family too.

Our 175 fits in the existing barn perfectly, something a wider machine probably wouldn't do - I consider that free storage. Having said that I'd still love to have a TD-15C for the wider blade and traction, of course along with a 175 (like HEF member dhutch). I'm a bit jealous of these guys like Nitelite with big money that can have a loader, dozer and big green tonka truck too. LOL!

Loose rocks like to make their way around a narrow loader bucket. If I were looking at a dozer, I'd consider finding a cherry TD-15C. They're cheaper than Cats. Most C model parts can still be had and they're easy to work on. There is no denying Cat has them all beat on parts and resell, but they seem more difficult to work on and you a pay a premium because it's Cat. I'd still consider a D6D, then D6C. Couple of years ago we found a premium D6C for $32,500!! It had an impressive resume that I suppose justified the cost. New undercarriage and was sitting on a pile of dirt from a 2+ acre pond it had just built. For trackloader, probably a 953 or 955. Some of the JD 650's dozers with the six-ways would be nice too, but $$.

I had to google "karst window". The definition seems to describe it perfectly except the limestone wall part as you noted. But there is limestone on the place. We live in Limestone County. I should see if the sink hole has grown any. I haven't checked it since I took those pictures probably 3 year ago. It's on a hill base, but still uphill from a lower spring. The closest spring is probably 600' away. I'm itching to build a pond at that particular spring, but have reservations about whether the TL is right for the job. I'm afraid of getting it stuck with the weight and narrow pads. This fall would've been a perfect time. We had a bad drought. The spring was dryer than I've ever seen although it still had water.

Would be glad to answer any questions. I may be in and out on the net for a week or two. We just closed on a house and 14 acres and will be working to get the data line in next week. Lots of projects ahead of me. Gonna have to put my two little helpers to work.

Merry Christmas and Happy New Year to you and your family too.

Hi Clark, yup we reinforced that boom just before we took the engine out of the loader. Figured at roughly 1500 lbs, the little boom could use all the help it could get. It still has some weak points, but it handled the engine pretty good as long as we minimized the swaying side to side. We had just a bit of paint left over from the fuel tank resto job, so we smeared it on to keep the rust down. Happy Holidays!

Nitelite

Senior Member

Settle down boone, you could have a big green Tonka truck too if you would quit buying toys like houses and spend that money on something really useful! My bucket list got shorter when that thing fell out of Santas sled!

Hi Boone, thanks for your well-considered response! I would love to be in the position to have both a larger TL and dozer! I don't know if you are familiar with the likes of my JD 350, but it is really a baby-TL. It's around 40 horse and 10K lbs. A good oak sapling is a bit too much for it, though it can drop most cedars all day long! Though some of the cedars around here are even too big (we have a few that are about 24" diameter!). Even though I was hoping to hold out for the right dozer with a six-way, I pulled the trigger on the 955K. An almost pristine SALT undercarriage was just too hard to pass up. Couldn't find a good excuse to pass it up. It will do everything that I need (well, almost everything, but I have tractors to do that part).

This seems like a good place to share a story about my dad's farm where I grew up. When I was a freshman in college he had another pond built. The conservation department did the lay-out and the contractor, Clark, came by with his operator. Clark pointed to one spot and told his operator "don't drive there". It looked just like the rest of the area, so it seemed a little odd.... well, the operator drove there and the track loader sank. It was so deep you could lean with your elbow on the top of the ROPS! The bottom of the tracks were a good six feet down. It looked like someone had used a sod-cutter around the sides of the crawler! It had gone straight down. Clark told my dad "cut 7' and 10' logs, a lot of them". They used the bucket to lift the front of the loader and shove the 10' sticks under the tracks then would lay the 7' logs cross-wise. They put about a cord of wood under the machine but it eventually was high enough that they drove it right out! Of course, they sank it even worse two days later! Dad said they probably used two cords of wood on that one! Anyhow--it seems to me you could do your pond with the 175 as long as you are careful. Of course, start at the perimeter where it is solid and work towards the softer areas. You might end up with an island or peninsula, but I think you would find that they would be dry enough to tackle from the sides. That's what they did on Dad's pond, and it ended up being a very beautiful pond!

--Cavin'

This seems like a good place to share a story about my dad's farm where I grew up. When I was a freshman in college he had another pond built. The conservation department did the lay-out and the contractor, Clark, came by with his operator. Clark pointed to one spot and told his operator "don't drive there". It looked just like the rest of the area, so it seemed a little odd.... well, the operator drove there and the track loader sank. It was so deep you could lean with your elbow on the top of the ROPS! The bottom of the tracks were a good six feet down. It looked like someone had used a sod-cutter around the sides of the crawler! It had gone straight down. Clark told my dad "cut 7' and 10' logs, a lot of them". They used the bucket to lift the front of the loader and shove the 10' sticks under the tracks then would lay the 7' logs cross-wise. They put about a cord of wood under the machine but it eventually was high enough that they drove it right out! Of course, they sank it even worse two days later! Dad said they probably used two cords of wood on that one! Anyhow--it seems to me you could do your pond with the 175 as long as you are careful. Of course, start at the perimeter where it is solid and work towards the softer areas. You might end up with an island or peninsula, but I think you would find that they would be dry enough to tackle from the sides. That's what they did on Dad's pond, and it ended up being a very beautiful pond!

--Cavin'