-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making a Cutting Edge

- Thread starter alaskaforby4

- Start date

Exactly! Most major advances are made by us misfits, one way or another, lol!Some times you just got to give a lash at things yourself even if they may be a bit mad (not saying this idea is)(more my own).

Good for the soul

alaskaforby4

Senior Member

I recently purchased a Hypertherm 65 Plasma cutter, which really spurred this whole "cutting edge" thing on. It's opened up so many new possibilities! Truly an amazing tool. Yesterday I was practicing with the gouging tip removing the welds from a dented panel. So much funner than grinding everything!

The more I look at detailed schematics of things the more I realize how 2 dimensional stuff starts out as, then welding together to make something useful, the possibilities are really endless.

The more I look at detailed schematics of things the more I realize how 2 dimensional stuff starts out as, then welding together to make something useful, the possibilities are really endless.

alaskaforby4

Senior Member

One of the edges I was going to "make" was flippable for another season. I did give hardfacing the lip with stick a go. The flat welding turned out okay. After that I gave going up the sides a try, I was able to make the 7018 rod behave okay, but when switching to the stoody 31 rod I could not make it go uphill,downhill, drag, push, anything! It all kind of boogered up, is this just the nature of the type of rod? what can I try to make it look a little more presentable? Here's a video of the flat work

John C.

Senior Member

I've never been able to run hard face out of position and make it look good. When doing sides of something I've either accepted that it will look like crap or I took the subject off the machine and turned it so that I was welding flat.

I Hardface with wire its a challenge to to the sides its easier to cheat and put on a piece of ar or the little wear blocks if you do have to buy hardface supplies talk with your professional welding store about your application as there are so many different types time and money to be lost using the wrong product

I didn't catch what size rod you had but the spec sheet shows only flat over 1/8 inch

https://mam.esab.com/assets/1/BDBA5...E71D60CC5/V410011-en_US-FactSheet_Main-01.pdf

I like your tire sipes also

I didn't catch what size rod you had but the spec sheet shows only flat over 1/8 inch

https://mam.esab.com/assets/1/BDBA5...E71D60CC5/V410011-en_US-FactSheet_Main-01.pdf

I like your tire sipes also

Years ago I ran some rod that was acceptable for downhand passes, but then I was running a Miller Big 40 at the time. I sincerely regret ever selling that big mother, smoothest DC stick machine I've ever run. Customer told me later my hardface lasted longer than the previous guys, I just wish I remembered what brand and number that rod was!

Nige

Senior Member

Vertical surface hardfacing - chocky bars or buttons. Works every time.

http://www.hensleyind.com/hensley-bimetallic-wear-products/

http://www.hensleyind.com/hensley-bimetallic-wear-products/

alaskaforby4

Senior Member

I've never been able to run hard face out of position and make it look good. When doing sides of something I've either accepted that it will look like crap or I took the subject off the machine and turned it so that I was welding flat.

Excellent, glad to hear it wasn't just my poor welding skils!

I Hardface with wire its a challenge to to the sides its easier to cheat and put on a piece of ar or the little wear blocks if you do have to buy hardface supplies talk with your professional welding store about your application as there are so many different types time and money to be lost using the wrong product

I didn't catch what size rod you had but the spec sheet shows only flat over 1/8 inch

https://mam.esab.com/assets/1/BDBA5...E71D60CC5/V410011-en_US-FactSheet_Main-01.pdf

I like your tire sipes also

Yes, typically I'll take these old edges and use them as wear bars. just all out of edges currently! The rod was 3/16's I found a Stoody amperage chart but id didn't say anything about flat/horz. That is good to know!

Tire siper was awesome, I'll make a seperate post on that sometime, waiting to get a comparison on ice with the newley treaded tires.

On our 966c Loader it has some hardfacing thats lasted the test of time. The beads on it must be 3/4" x 1/2" thick! I'm not sure what they put it down with but must have been a monster welder.Years ago I ran some rod that was acceptable for downhand passes, but then I was running a Miller Big 40 at the time. I sincerely regret ever selling that big mother, smoothest DC stick machine I've ever run. Customer told me later my hardface lasted longer than the previous guys, I just wish I remembered what brand and number that rod was!

alaskaforby4

Senior Member

DB2

Senior Member

I like the picnic bench 2. Getting sick of perching on rams an bosses

Looks handy for cleaning the windshield.

alaskaforby4

Senior Member

I started the bucket/cutting edge project, 1st up was to swap the couplers. Or rather put the pin grabber style on the larger bucket. I have a Hypertherm 85 plasma and it wasn't to happy about cutting the lower portion on the coupler on the left. It was 2" thick! I had to come at it from both sides.

Finally got them both off and started prep for re-attaching.

The pin grabber of course wouldnt fit between the old coupler and 1/4" had to come out of both sides. The gouging tip was quite fun to work with, much funner then a grinder, its amazing how intricate you can get with them, each swipe is like removing a layer of steel with a paint brush.

I didnt remove these ears as they attach to the core of the bucket and will be the main anchor for new coupler

Finally got them both off and started prep for re-attaching.

The pin grabber of course wouldnt fit between the old coupler and 1/4" had to come out of both sides. The gouging tip was quite fun to work with, much funner then a grinder, its amazing how intricate you can get with them, each swipe is like removing a layer of steel with a paint brush.

I didnt remove these ears as they attach to the core of the bucket and will be the main anchor for new coupler

alaskaforby4

Senior Member

alaskaforby4

Senior Member

alaskaforby4

Senior Member

alaskaforby4

Senior Member

Bls repair

Senior Member

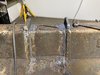

What’s the steel on the end of the edge for ? Is the main edge flat or rounded from wear?

alaskaforby4

Senior Member

The edges always wear out so fast, I put these extra wear plates on, now I can get another season out of the same edgeWhat’s the steel on the end of the edge for ? Is the main edge flat or rounded from wear?