Diesel Dave

Senior Member

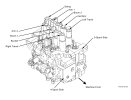

Check to see if the right side counter balance valve is stuck in its bore located in the head of the propel motor. The counterbalance valve has to shift in either direction to open the passage allowing pressure to the brake piston releasing the propel brake.Also, I am thinking there may be a different issue which is lagging from the original pump failure. I raised the machine up and was able to get the right track off the ground and tried to move forward and reverse to see if the track would spin and it would not but the pump would display 5600psi but no motion at all in either direction. I feel like this is from the original pump failure when the boom stopped as well.

.