William907

Member

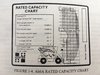

I just got this Hyster fork truck. I think it is a A80A, but I'm not sure.

The VIN is A116P****E. Since it ends with an E, I guess it was made in 1984.

It has sat for many year and was just about on its way to the dump. Since I'm a guy that's known to take free junk, I got it. It took about an hour to get its four cylinder Perkins running. All the hydraulics work but it won't move forward or backwards. The transmission was low on fluid so I filled it up, but the shaft from the transmission to the transfer case won't spin. Well, it spins just a little when it first starts up. I am thinking that there is some sort of electric solenoid that is keeping the transmission from going into gear.

It had two flat, and most likely ruined, 13.00-24 tires. I just happen to have six 14.00-24 tires off of a grader. Would it be a problem to put these slightly larger tires on this fork truck? It looks like there is plenty of room for them.

Any info, advise, or help, would be greatly appreciated.

The VIN is A116P****E. Since it ends with an E, I guess it was made in 1984.

It has sat for many year and was just about on its way to the dump. Since I'm a guy that's known to take free junk, I got it. It took about an hour to get its four cylinder Perkins running. All the hydraulics work but it won't move forward or backwards. The transmission was low on fluid so I filled it up, but the shaft from the transmission to the transfer case won't spin. Well, it spins just a little when it first starts up. I am thinking that there is some sort of electric solenoid that is keeping the transmission from going into gear.

It had two flat, and most likely ruined, 13.00-24 tires. I just happen to have six 14.00-24 tires off of a grader. Would it be a problem to put these slightly larger tires on this fork truck? It looks like there is plenty of room for them.

Any info, advise, or help, would be greatly appreciated.