bdiwearparts

Well-Known Member

No.1 When a new product is introduced, our design team “translates” the drawings supplied into product sheets:

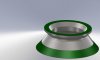

No.2 A 3D model of the product is created for better understanding and will be used for simulations

No. 3 Technicians then performs simulations to determine best quality control and pouring method

No. 4 Patterns are made for each product

No.2 A 3D model of the product is created for better understanding and will be used for simulations

No. 3 Technicians then performs simulations to determine best quality control and pouring method

No. 4 Patterns are made for each product