BCOG

Member

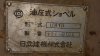

Hi, new user of the site. I have a little collection of older machines growing on my property. The heaviest of which being a 1986 Hitachi UH181.

Since moving it up the very steep grade while dragging a 20,000lb rubber track carrier behind it 2 years ago; it has sat under a pole barn.

Started it today, it runs no problem. I replaced the inline fuel pump because the old one wasnt wired in with a fuse and blew, and put 2 new batteries in.

There seems to be a decent amount of fluid in the hydraulic reservoir (AW32?)

Not sure which fluid it takes.

The hydraulic controls are baaaarely working if at all, juust got the boom lifting. I pressure washed all the rollers in the tracks as they had dried clay like concrete in them.

Cant get it to move now.

I am not a mechanic, but I am mechanically inclined. where I lack all knowledge base is about hydraulic systems. Where should i begin?

Sorry for the long story! Any info helps!

Cheers and thanks for your time

Since moving it up the very steep grade while dragging a 20,000lb rubber track carrier behind it 2 years ago; it has sat under a pole barn.

Started it today, it runs no problem. I replaced the inline fuel pump because the old one wasnt wired in with a fuse and blew, and put 2 new batteries in.

There seems to be a decent amount of fluid in the hydraulic reservoir (AW32?)

Not sure which fluid it takes.

The hydraulic controls are baaaarely working if at all, juust got the boom lifting. I pressure washed all the rollers in the tracks as they had dried clay like concrete in them.

Cant get it to move now.

I am not a mechanic, but I am mechanically inclined. where I lack all knowledge base is about hydraulic systems. Where should i begin?

Sorry for the long story! Any info helps!

Cheers and thanks for your time