When the primary boom is raising, does the platform stay level throughout the raising process?

Does the platform remain level all the way through the boom lowering process?

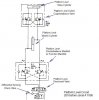

The machine uses a master-slave system to keep the platform level throughout the boom raising / lowering functions.

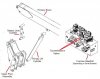

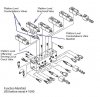

The Master cylinder (C) is pinned on the upper pivot assembly near the pivot end of the primary boom. The other end of the Master cylinder is pinned to the primary boom. As the primary boom is raised, the rod end of the Master cylinder is pulled out from the act of the primary raising. The oil in the rod end of the master cylinder is forced to travel to the Slave cylinder (E). Here it will manipulate the counterbalance valves on the Slave cylinder and force the cylinder to retract.

Counterbalance Valve (B) is in the circuit to ensure the oil goes to the slave cylinder and not through the function manifold back to tank.

If the Platform remains level throughout the range of motion of the primary boom up/down, then the condition of the Counterbalance Valve and the Master Cylinder should not be suspect.

If the platform does not stay level during boom up and down, then it is possible that the oil is bypassing in the master cylinder or the function manifold.

Bad packings in the master cylinder, a swell in the master cylinder barrel, trash/bad o-ring on the counterbalance valve, or a crack in the function manifold itself.

When the toggle switch for platform level is used, Valve A opens, letting oil into the circuit. If there is bypass in one of the mentioned components, then you will experience the results you are having.

View attachment 97573