qarm

Member

Many Thanks VooDoo Mojo

The setting of the machine at present is how I last put it away in my shed and that is :

All outriggers up

Booms fully down as we do set for towing.

Was operational last time I used it.

Last time I used it when putting in the shed I cleaned the platform and in doing so lifted the boom from the lain controls rather than the platform that I normally do just for cleaning purposes.

Then when I went to use it after charging and turned it on all the outrigger lights flashed and kept flashing.

They normally stop flashing and allow me to put the outriggers down and the light for each then come on normally.

The condition that they are in presently with the outrigger lights flashing it does not allow me to put any outriggers down.

The turntable attempts to rotate but of course it cant because the boom is fully down and does not allow it to turn because it is locked in the V rest.

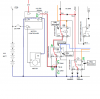

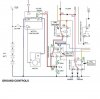

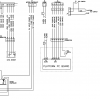

Idid some testing in accordance with your schematic.

With the machine off and in its present fully stowed position I checked the following.

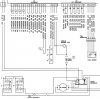

The large black plug to make sure the all the connectors are in their positions,

Using a tester I did the following:

With the plug unplugged I checked pin 25 and 24 and found complete circuit.

I checked pin 22 and pin 10 and found complete circuit

I tested 16 and 4 and found complete circuit

I tested pin 20 and pin 8 and found open circuit

I tested pin 30and pin 19 and found open circuit

I tested pin 33 and 23 and found complete circuit

I tested pin 14 and pin 3 and found complete circuit

I tested pin pin 18 and pin 6 and found open circuit

I tested pin 29 and pin 17 and found open circuit

I tested pin 32 and 21 and found complete circuit

So these all appear to be as per the schematic

The LS27 I do not know where that is although it tested in the circuit with LS2 and LS11 ok it says in the schematic that LS27 is turntable but I do not see any limit switch for the turntable unless it is inside the gear assembly area which is really hard to tell with all booms down etc.

I tested the batteries with the voltmeter and found each of the 4 batteries to be 6 volt or slightly under and reconnected and tested at the quick release and found just under the 24 volts which on my tester then showed about 23 volts fully charged.

After doing this testing I checked the large plug and re plugged it in and turned the machine on and found the lights will still flash and alarm sound preventing from activating the outriggers.

The setting of the machine at present is how I last put it away in my shed and that is :

All outriggers up

Booms fully down as we do set for towing.

Was operational last time I used it.

Last time I used it when putting in the shed I cleaned the platform and in doing so lifted the boom from the lain controls rather than the platform that I normally do just for cleaning purposes.

Then when I went to use it after charging and turned it on all the outrigger lights flashed and kept flashing.

They normally stop flashing and allow me to put the outriggers down and the light for each then come on normally.

The condition that they are in presently with the outrigger lights flashing it does not allow me to put any outriggers down.

The turntable attempts to rotate but of course it cant because the boom is fully down and does not allow it to turn because it is locked in the V rest.

Idid some testing in accordance with your schematic.

With the machine off and in its present fully stowed position I checked the following.

The large black plug to make sure the all the connectors are in their positions,

Using a tester I did the following:

With the plug unplugged I checked pin 25 and 24 and found complete circuit.

I checked pin 22 and pin 10 and found complete circuit

I tested 16 and 4 and found complete circuit

I tested pin 20 and pin 8 and found open circuit

I tested pin 30and pin 19 and found open circuit

I tested pin 33 and 23 and found complete circuit

I tested pin 14 and pin 3 and found complete circuit

I tested pin pin 18 and pin 6 and found open circuit

I tested pin 29 and pin 17 and found open circuit

I tested pin 32 and 21 and found complete circuit

So these all appear to be as per the schematic

The LS27 I do not know where that is although it tested in the circuit with LS2 and LS11 ok it says in the schematic that LS27 is turntable but I do not see any limit switch for the turntable unless it is inside the gear assembly area which is really hard to tell with all booms down etc.

I tested the batteries with the voltmeter and found each of the 4 batteries to be 6 volt or slightly under and reconnected and tested at the quick release and found just under the 24 volts which on my tester then showed about 23 volts fully charged.

After doing this testing I checked the large plug and re plugged it in and turned the machine on and found the lights will still flash and alarm sound preventing from activating the outriggers.