colson04

Senior Member

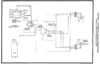

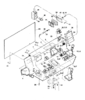

The engine runs very well. Started right up with a replacement coil installed. I could only get the hydraulic steering, basket swivel, basket level, and boom telescoping in and out functions to work. Could not get the machine to move, swing, or elevate. Shifting the diverter valve to "axles" rather than steering does attempt to pull the axles in, but I'd bet the machine needs to be rolling for that to happen. I'm thinking there may not be a relay string pulling in but I've not studied a print yet so just guessing at this point. The boom elevation toggle switch in the ground control panel feels lazy and I'm kinda thinking the switch may be bad. If so, the boom switch in the basket is in series with this ground control position so is suspect till proven otherwise. I found a couple of solenoid valves with the wires corroded off but jumpering the coils did make them operate but still couldn't get the boom to react. The electric auxiliary hydraulic pump motor is not operational and I put 12VDC to it directly. The magnetic solenoid which supplies power to this motor closes as it should but the motor doesn't operate. I need to do some more reading to ascertain just what this auxiliary pumping unit is for.

Auxilliary pumping unit gets you back to the ground should your engine shut down and fail to restart. Running out of fuel being usual culprit. It won't lift anything (at least mine won't) but it will get you back to earth. My 45HA only.has controls to activate auxilliary pump from basket.