Egetebee

Well-Known Member

Hi Everyone,

EX120.

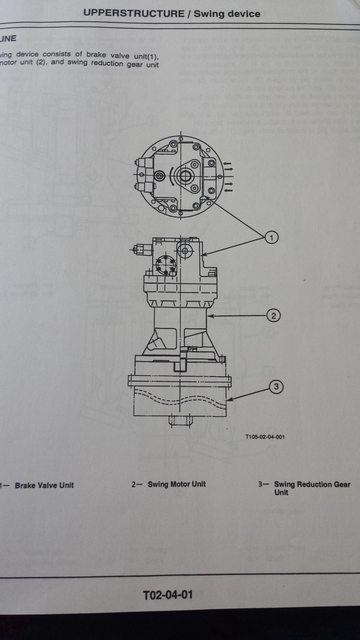

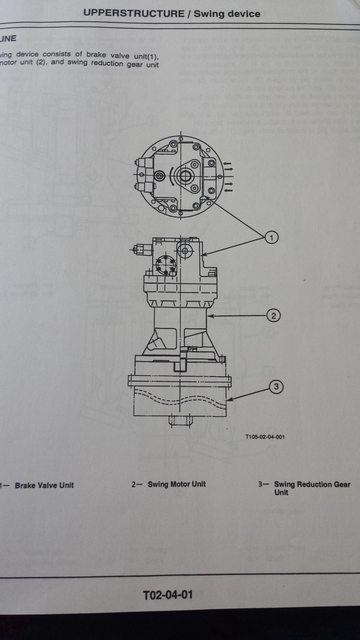

Have two issues with the swing motor reduction gear unit.

1. The unit is leaking gear oil through the slew ring & onto the belly almost as fast as it goes in, almost...

2. The reduction gear unit housing is cracked at the bolt support flange holes but has been stable for a long time and seems to work just fine besides the gear oil leak.

I don't know if the cracked support holes are related to the leaking gear oil and was hoping to receive some constructive critique of the situation and possible repair solutions. It's a personal machine used to do some work on our lot and quite frankly running low on funds to repair these large ticket items.

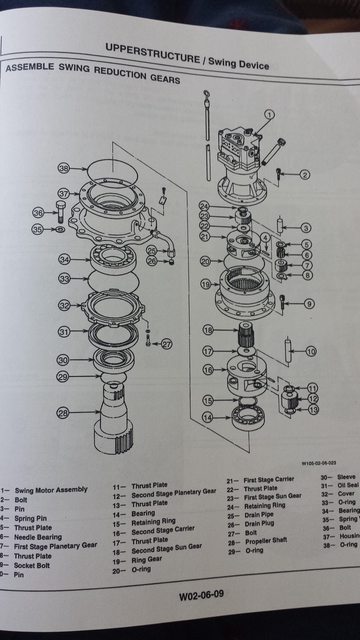

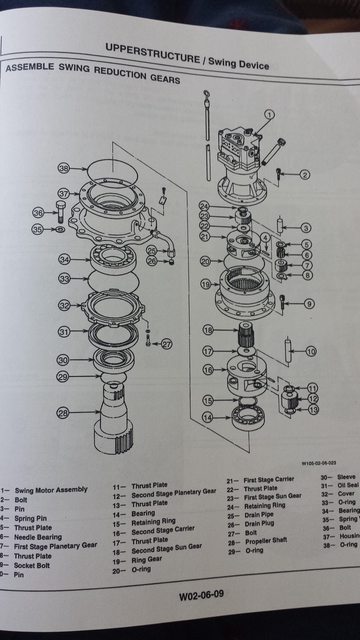

I've read in several posts that the leak may be a reduction gear shaft seal which some have said is a reasonably easy repair, which I'm hoping. I don't have a problem pulling the swing motor assembly to make DIY repairs.

So the questions are, based on the gear shaft seal being located in the reduction gear housing;

1. Can the flange housing be welded?

2. Is the gear shaft seal replaced from the bottom of the unit or do I need to split the swing motor section from the reduction gear housing section?

3. Would anyone happen to have pictures of the bottom of the assembly or instructions on how to do the seal change?

4. Worse come to worse, can just the lower reduction gear unit be replaced somewhat low cost?

Any help would be much appreciated?

Many Thanks!

EX120.

Have two issues with the swing motor reduction gear unit.

1. The unit is leaking gear oil through the slew ring & onto the belly almost as fast as it goes in, almost...

2. The reduction gear unit housing is cracked at the bolt support flange holes but has been stable for a long time and seems to work just fine besides the gear oil leak.

I don't know if the cracked support holes are related to the leaking gear oil and was hoping to receive some constructive critique of the situation and possible repair solutions. It's a personal machine used to do some work on our lot and quite frankly running low on funds to repair these large ticket items.

I've read in several posts that the leak may be a reduction gear shaft seal which some have said is a reasonably easy repair, which I'm hoping. I don't have a problem pulling the swing motor assembly to make DIY repairs.

So the questions are, based on the gear shaft seal being located in the reduction gear housing;

1. Can the flange housing be welded?

2. Is the gear shaft seal replaced from the bottom of the unit or do I need to split the swing motor section from the reduction gear housing section?

3. Would anyone happen to have pictures of the bottom of the assembly or instructions on how to do the seal change?

4. Worse come to worse, can just the lower reduction gear unit be replaced somewhat low cost?

Any help would be much appreciated?

Many Thanks!