I've been struggling for two months with my DEF system, and now the DFP is not regenning but needs to.

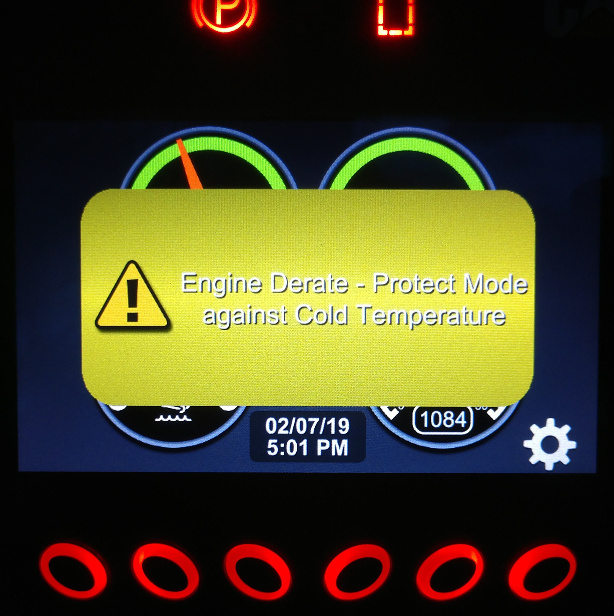

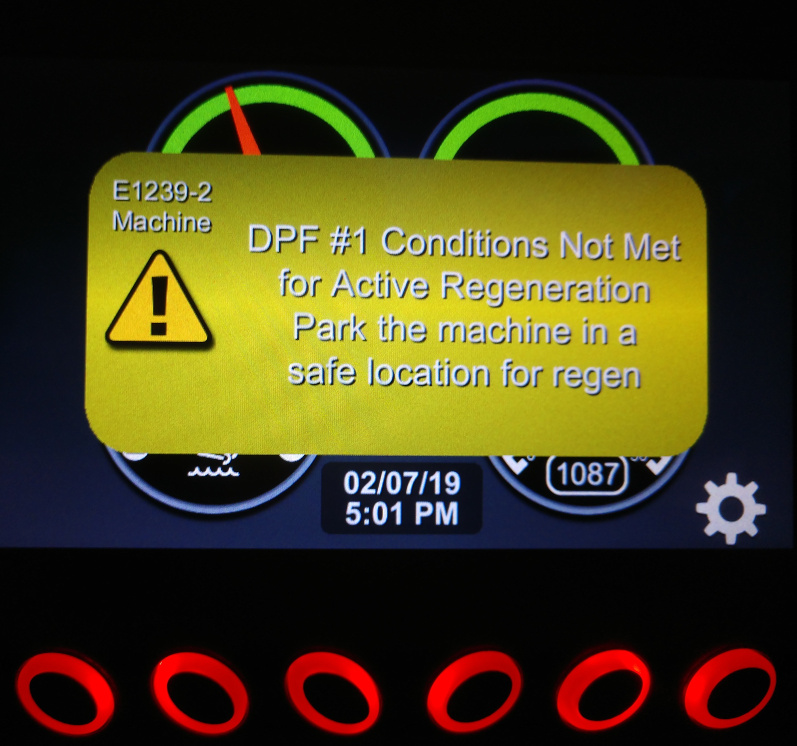

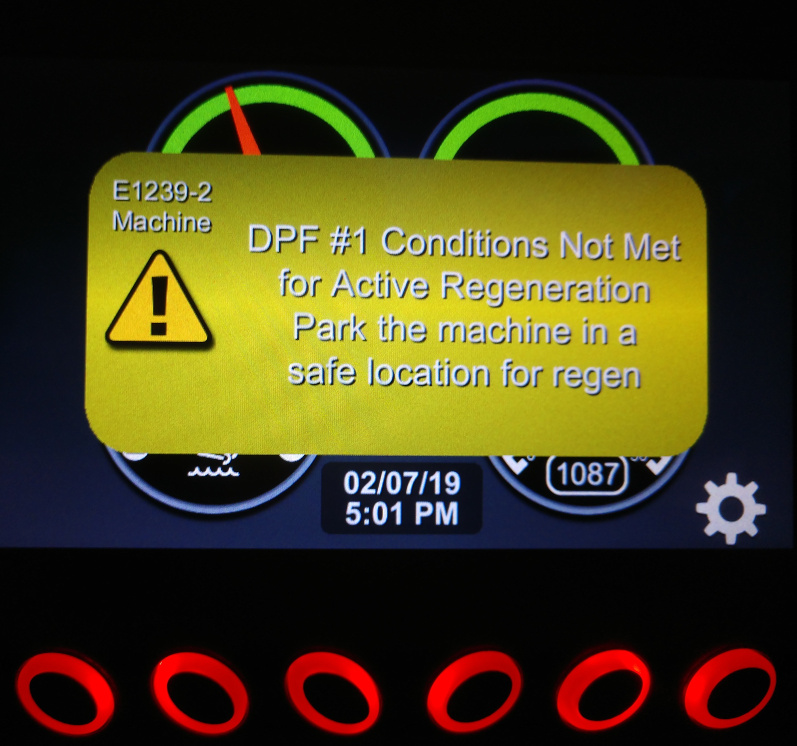

This is a 2016 Cat 299D2 XHP (DX200946) which I've just rebuilt from total burnout. Everything works except for this and I've done all calibrations. The symptom starts on engine start with this:

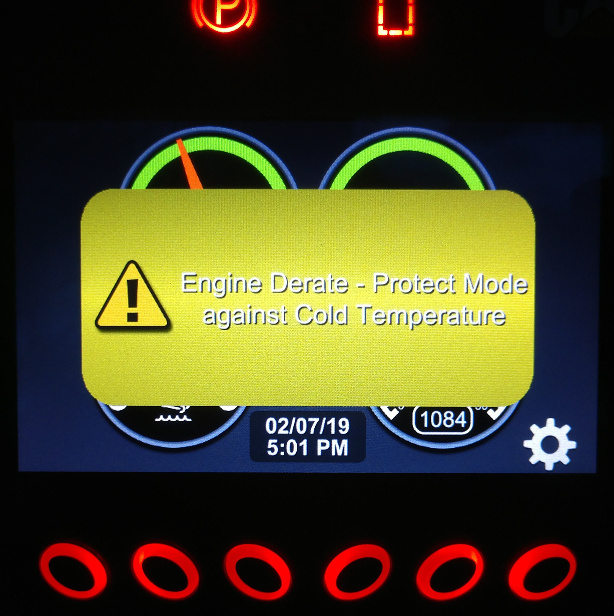

... and ~45 minutes later comes up with this:

So I thought it's a DEF circulation problem. I flushed the injector ($1,200) through the nipples overnight, and then I attached the garden hose to the injector port (90psi), applied 12v and white stuff vomited out the nipples. I can hear the solenoid clicking as I apply and remove 12v. So I let that flush overnight. Didn't help.

I suspected the DEF pump ($2,400) and took that apart examining the ports, gears, filter chamber, but no blockage. I reinstalled the pump and ran a clear tube from the DEF tank to the pump. It did suck for 1.5 minutes, but then reversed as if clearing. I put pins in one of the pump's 3 phase wires and to the ground. 2.8 vAC as expected, which went away after 1.5 minutes then came back, presumably in reverse.

I feel sure that fluid is getting circulated, although it doesn't look like very much volume or pressure, basically a trickle, although the injector port is quite small. I put the plastic tube on the pump output and it trickles just enough to not break into drops. I've removed the DEF filter and no change. I've replaced the filter and space-taker-upper plug with new. I took the injector off the manifold and wrapped it in a baggie, started the engine, and nothing came out.

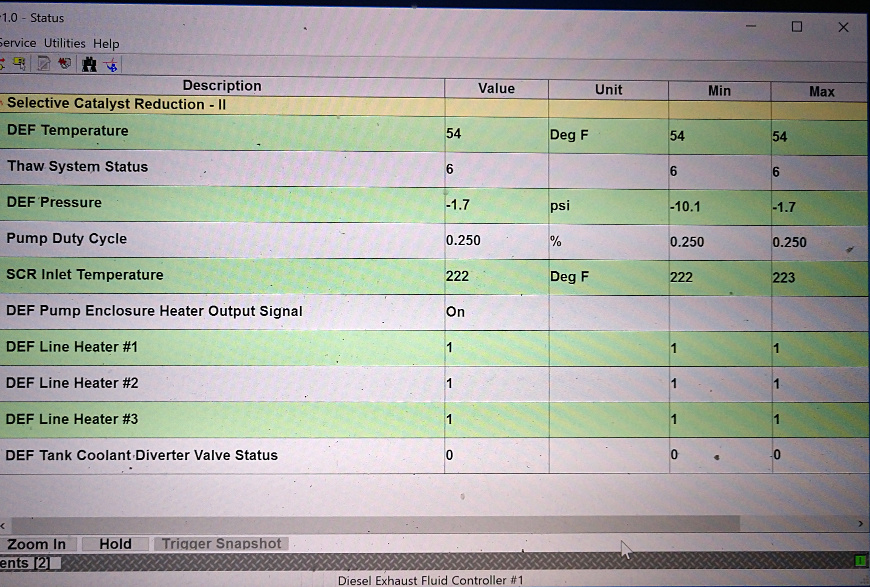

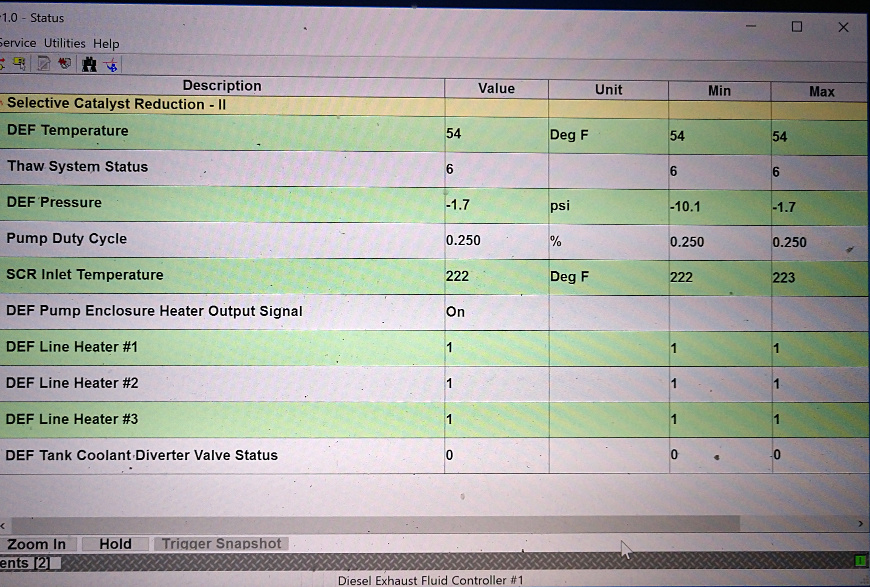

Here's what ET says:

Huh? DEF Pressure negative? (Although Max 21.7) Must be in the clear cycle, right?

DEF Pressure now is 1.7psi?

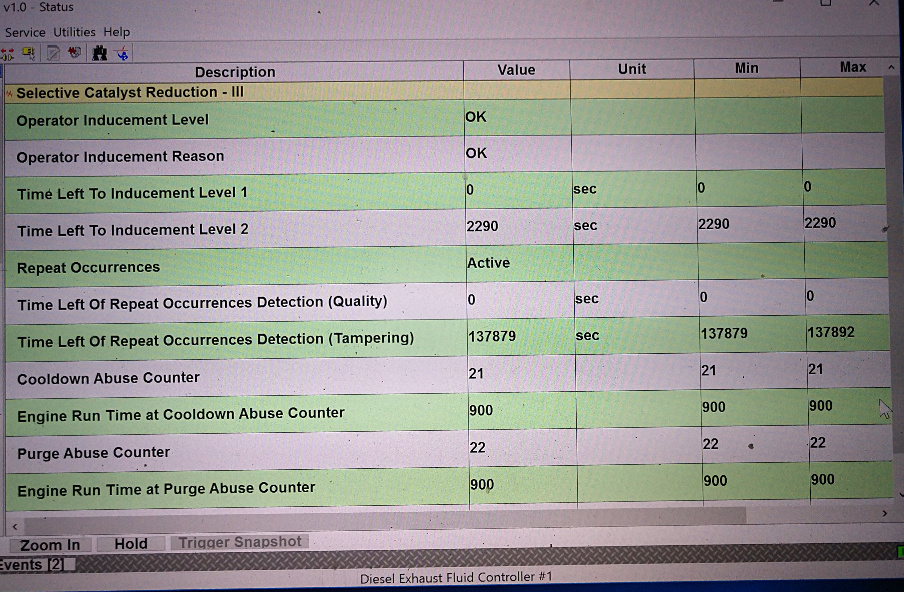

So that's a problem.

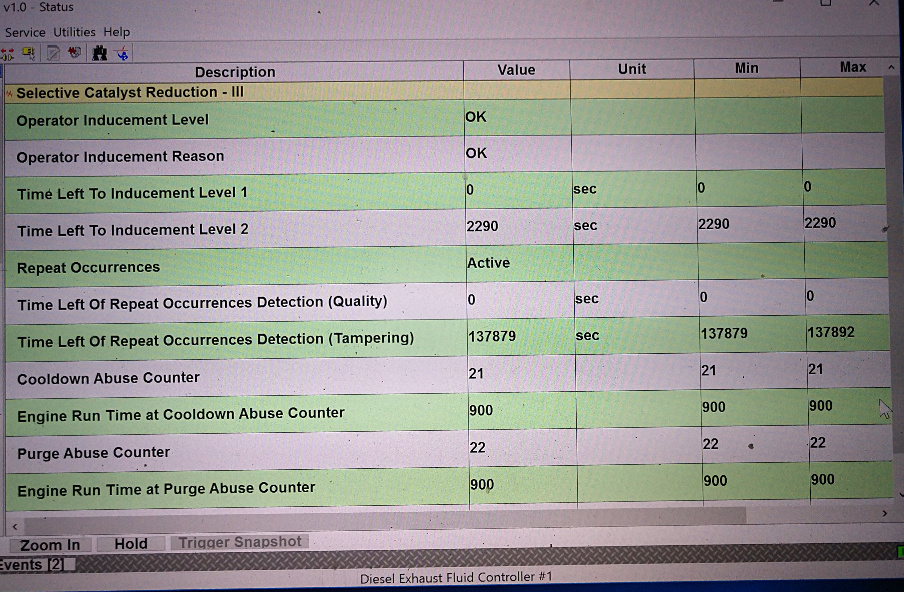

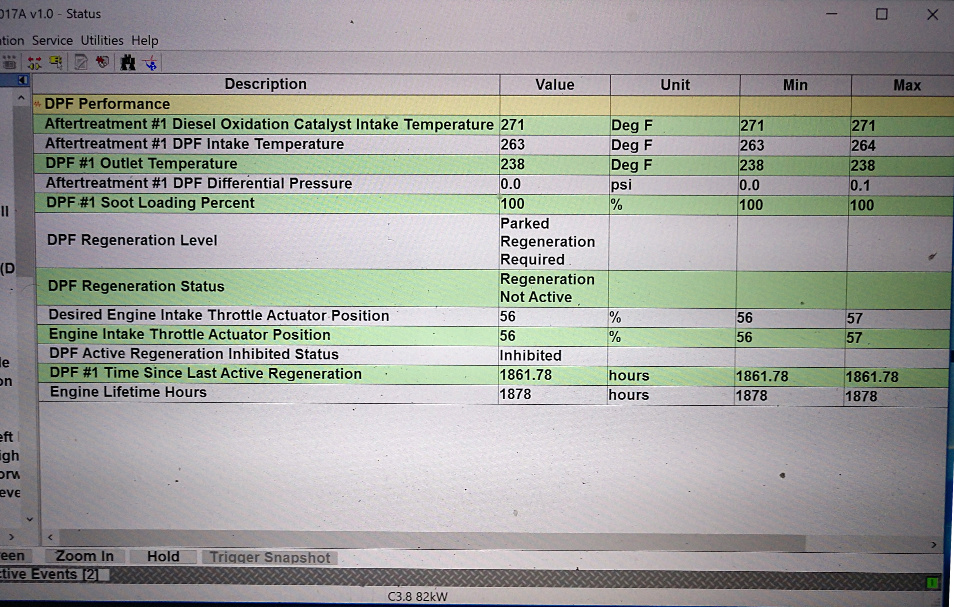

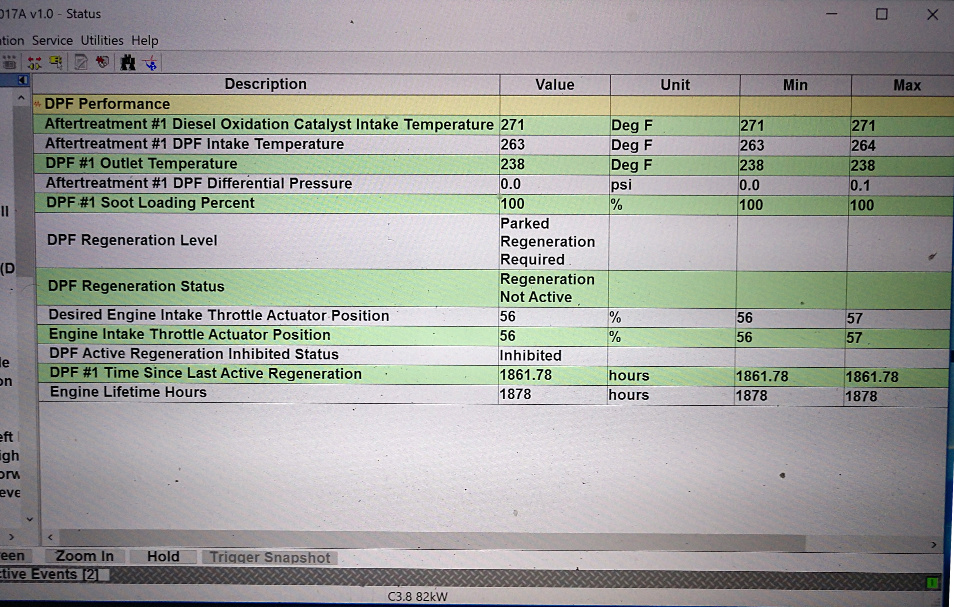

Now I've run the engine so long struggling with this, that DPF needs to regen.

... but it's inhibited. Inhibited by what? Nothing? Could it know that it's not getting DEF? Why should oxides of nitrogen have anything to do with carbon build-up?

Park it in safe location and then what? Wave my hands in the air like I just don't care? It already is parked in a safe location.

I try to do a manual regen and it claims success in starting, but it never actually starts. I've tried with throttle at zero, and at max, waiting 15 minutes for each but status is always not in regen cycle, and Inhibited.

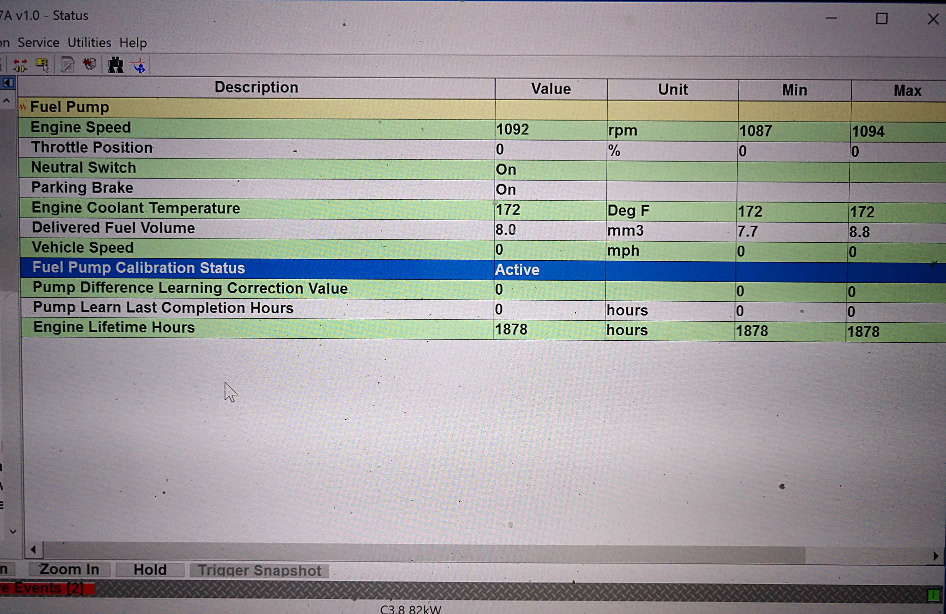

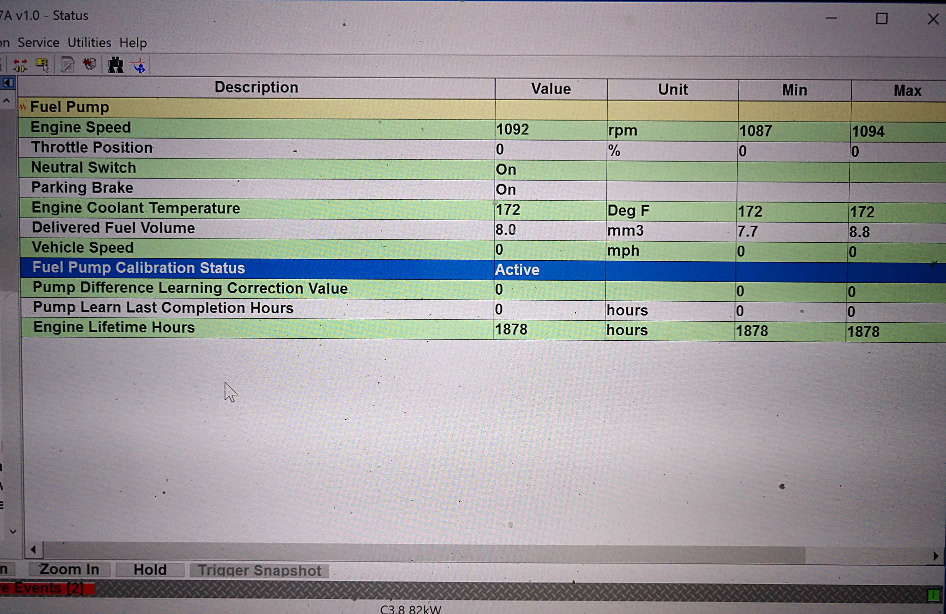

The only other abnormality in the whole system is the fuel pump is showing to be recalibrating. I'd initiated this two weeks ago and interrupted it because of the DPF, but it's still showing active. I tried to calibrate it again but nothing seems to be happening.

This is a 2016 Cat 299D2 XHP (DX200946) which I've just rebuilt from total burnout. Everything works except for this and I've done all calibrations. The symptom starts on engine start with this:

... and ~45 minutes later comes up with this:

So I thought it's a DEF circulation problem. I flushed the injector ($1,200) through the nipples overnight, and then I attached the garden hose to the injector port (90psi), applied 12v and white stuff vomited out the nipples. I can hear the solenoid clicking as I apply and remove 12v. So I let that flush overnight. Didn't help.

I suspected the DEF pump ($2,400) and took that apart examining the ports, gears, filter chamber, but no blockage. I reinstalled the pump and ran a clear tube from the DEF tank to the pump. It did suck for 1.5 minutes, but then reversed as if clearing. I put pins in one of the pump's 3 phase wires and to the ground. 2.8 vAC as expected, which went away after 1.5 minutes then came back, presumably in reverse.

I feel sure that fluid is getting circulated, although it doesn't look like very much volume or pressure, basically a trickle, although the injector port is quite small. I put the plastic tube on the pump output and it trickles just enough to not break into drops. I've removed the DEF filter and no change. I've replaced the filter and space-taker-upper plug with new. I took the injector off the manifold and wrapped it in a baggie, started the engine, and nothing came out.

Here's what ET says:

Huh? DEF Pressure negative? (Although Max 21.7) Must be in the clear cycle, right?

DEF Pressure now is 1.7psi?

So that's a problem.

Now I've run the engine so long struggling with this, that DPF needs to regen.

... but it's inhibited. Inhibited by what? Nothing? Could it know that it's not getting DEF? Why should oxides of nitrogen have anything to do with carbon build-up?

Park it in safe location and then what? Wave my hands in the air like I just don't care? It already is parked in a safe location.

I try to do a manual regen and it claims success in starting, but it never actually starts. I've tried with throttle at zero, and at max, waiting 15 minutes for each but status is always not in regen cycle, and Inhibited.

The only other abnormality in the whole system is the fuel pump is showing to be recalibrating. I'd initiated this two weeks ago and interrupted it because of the DPF, but it's still showing active. I tried to calibrate it again but nothing seems to be happening.

Last edited: