josiahnt

Member

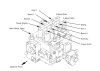

I have a 2012 350G 9000 hrs, that is building excessive pressure in a spool cap and actually cracking the mounting flange to relieve the excess pressure. This cap has been replaced with a brand new one and cracked again within 30 mins run time. My mechanic teed in a pressure gauge on it and routed it to the cab. The pressure seems to climb as soon as the oil starts warming up and in a few minutes will exceed 600 psi. Once the pressure starts to build, any operation of the machine causes it to climb, including traveling. I have included a couple pictures, one of the part on the machine and the part in the Deere diagram. Any ideas?