Robert0769

Senior Member

No. Only coolant analysis has two levels - 1 & 2. Normally a Level 1 is done every 500-1000 hours and a Level 2 every 2-4000 operating hours.

Approximately how many gallons of fuel were you burning in a typical day..? The normal way is to relate how many gallons of fuel are burned for every quart of top-up oil added, provided that the engine has no visible external oil leaks.

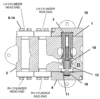

Testing the implement pressure is not as simple as it is on some machines. The test points are under the floor and you need to remove both the operator seat and the floor panel to access them. See the illustration below. If you want a full procedure send me a PM with your email address.

View attachment 199483

Roughly 100-110 gallons of fuel a day to 3/4 a gallon of oil