8V149 Detroit

Active Member

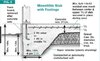

I am new to the form and shop talk seemed like where this should go. I'm going to be building a shop in the future and wondering what would be thick enough for heavy equipment, I was thinking 8 inchs thick but The biggest machine I have is a 300 series machine currently but will probably get something bigger in a few years