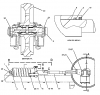

Can anyone help with the best way to change the track adjuster seals on a Cat 939 .Most of the excavator ones we have done had a bolt on head with the seals in there . This just has an open end tube that the rod goes into .

There is a seal, i assume is just a wiper seal in the end of the tube.

Problem is , the tube is almost hard up against the front track frame support.The Chrome rod goes though a hole in the support. Does the Track frame have to be removed . Or does the recoil spring/adjuster assemberly come off without the recoil spring Taking my head off .

There is a seal, i assume is just a wiper seal in the end of the tube.

Problem is , the tube is almost hard up against the front track frame support.The Chrome rod goes though a hole in the support. Does the Track frame have to be removed . Or does the recoil spring/adjuster assemberly come off without the recoil spring Taking my head off .