serial number 7yb 00800.

having major issues with my dozer. stopped using it because it was unable to work.

as you shift into first gear, it doesnt engage you need to rev it quite abit to engage it and move and once its moving if you reduce rpm the gear feel like its gone back into neutral.

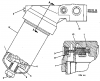

touched the transmission pump it was quite hot, i feel the pump has lost pressure!

checked the transmission filters at the back they were ruined looked like the pressure had sucked them in.

any ideas what could be wrong?

having major issues with my dozer. stopped using it because it was unable to work.

as you shift into first gear, it doesnt engage you need to rev it quite abit to engage it and move and once its moving if you reduce rpm the gear feel like its gone back into neutral.

touched the transmission pump it was quite hot, i feel the pump has lost pressure!

checked the transmission filters at the back they were ruined looked like the pressure had sucked them in.

any ideas what could be wrong?