BrianGrenier

Senior Member

No travel, no boom, no swing issue:

First and before the hydraulics locked out,

I replaced the starter as the starter brushes and commutator fried themselves with all systems good at the time, electric system was charged to 24.4+- no issues anywhere, great batteries.

So the starter went in just fine and the machine started with the first spin of the key,

then

I put the yellow hydraulic safety lock down at the left armrest and not much happened. The controls acted like they were ready to work, I could get some boom down and it seemed to want to boom up, but no...

Putting the safety lock down makes the hydraulic lines shake as pressure seems to rise.

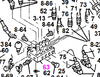

Looking at the schematic, I see there is a hyd loc solenoid 111-4871

1999 caterpillar 320 B LL processor serial number 9Js00308

First and before the hydraulics locked out,

I replaced the starter as the starter brushes and commutator fried themselves with all systems good at the time, electric system was charged to 24.4+- no issues anywhere, great batteries.

So the starter went in just fine and the machine started with the first spin of the key,

then

I put the yellow hydraulic safety lock down at the left armrest and not much happened. The controls acted like they were ready to work, I could get some boom down and it seemed to want to boom up, but no...

Putting the safety lock down makes the hydraulic lines shake as pressure seems to rise.

Looking at the schematic, I see there is a hyd loc solenoid 111-4871

1999 caterpillar 320 B LL processor serial number 9Js00308