Monkeywithawrench

Senior Member

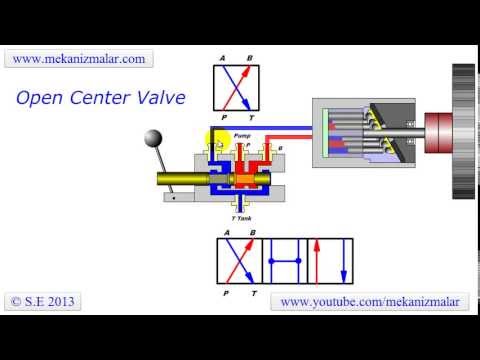

I need to add a winch to a Komatsu WA250-1. I'll be putting a Pull Master H10 onto the machine. My question is....is there a power beyond port anywhere on this machine?? The machine has the stock 2 spool valve setup for bucket lift and dump. I thought about tagging into the return line off the valve block but its a solid steel line off the block to a manifold block by the tank. That means taking the line off, cutting, welding, and then plumbing the motor spool valve in.

Looking at the service manual and at the machine, I don't see any extraneous ports that I might be able to unplug and tap into on the hydraulic pumps.

Has anybody added a grapple or 3rd function to one of these and, if so; how did/would you go about plumbing into this??

Thank you!!!

Looking at the service manual and at the machine, I don't see any extraneous ports that I might be able to unplug and tap into on the hydraulic pumps.

Has anybody added a grapple or 3rd function to one of these and, if so; how did/would you go about plumbing into this??

Thank you!!!