I was using my 955 k today and a puff of smoke came out the fan and it quite moving. It's 102 out today and it was way too hot out to start investigating. If you speed the motor up past idle you can hear a squealing noise and smell of burning rubber. Looks like the fan and water pump belts are on and ok but it's too hot to look any farther. Anyone have any ideas?

-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

955k won't move

- Thread starter Pete1468

- Start date

If the fan quit moving check the fan hub bearings ,if the tractor quit moving check drive plate bushings..I was using my 955 k today and a puff of smoke came out the fan and it quite moving. It's 102 out today and it was way too hot out to start investigating. If you speed the motor up past idle you can hear a squealing noise and smell of burning rubber. Looks like the fan and water pump belts are on and ok but it's too hot to look any farther. Anyone have any ideas?

Bob

grandpa

Senior Member

They are easy to replace, but like Cmark stated, check the engine alignment. Those pucks usually last a long long time. All though its been a long long time since they made the K.

Nige

Senior Member

A machine Serial Number gets you the specifications & procedure for checking the coupling alignment .......... there is a difference in parts between early machines (85J1-4064) and later machines (85J4065-Up)

Nige

Senior Member

In the case of 61H the Serial Number break is at 61H891. Need to know if your machine is above or below that.

Nige

Senior Member

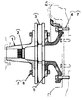

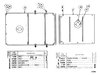

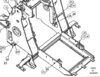

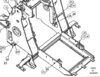

Here are the Specifications & the Disassembly/Assembly Instructions.

As CMark said above the first thing you need to be checking before starting work on the coupling is that the front & rear engine mounts are all in good order. Replace those mounts as necessary depending on condition before starting the coupling alignment process.

As CMark said above the first thing you need to be checking before starting work on the coupling is that the front & rear engine mounts are all in good order. Replace those mounts as necessary depending on condition before starting the coupling alignment process.

Attachments

Took it apart tonight, it's miss aligned. The pucks are tight on the top and loose by a 1/4 of an inch on the bottom. Is there shims on the motor mounts? I think I'll have to start it to raise and lock the arms up so I can inspect the front easier.

Nige

Senior Member

For machine S/N 61H463 there are shims available for the rear. Part Numbers are 6K-7195 (0.032") & 6K-7194 (0.064"). See ref 28 & 29 on the illustration.

If you read the measurement & adjustment procedure I posted above it's important to make sure that the front motor mounts are not in problems before you start changing the shimming on the rear.

If you read the measurement & adjustment procedure I posted above it's important to make sure that the front motor mounts are not in problems before you start changing the shimming on the rear.

The rear of the motor needs to go up. There's just 2hard steel washers in there at the rear. I'm going to try and find something to go in there. Both the rear mount bolts were loose so if something else was in there it feel out.

Dave Neubert

Senior Member

When you replace the drive biscuits leave all the bolts loose until you get all of them mounted it makes for easier installation