This is a bit weird and I am hopeful someone can help me out. I was running the other day and it started to loose drive and then bucket power and stopped. Still running fine not lights on. I got out and had dumped what looked like a significant amount of Hydraulic Fluid. I figured I had blown a hose or something.

So I lifted the cab and the inside was literally full of years of dirt and oil so I spent the next few hours digging, vacuuming and pressure cleaning to get to the point where I could see what was going on, still expecting a hose to be blown.

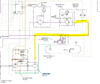

Now I can see what is going on and run the machine and nothing appears to be blown and no big leaks, one small one by nothing like what I expected. Hydraulic Tank is still 3/4 full so plenty of fluid and stiull no drive or bucket etc.

One thing it does do now is when I run it and then turn it off I get a loud gurgling sound as though the pump is full of air ?

Is there a way to bleed the pump ?

Any ideas or suggestions ?

So I lifted the cab and the inside was literally full of years of dirt and oil so I spent the next few hours digging, vacuuming and pressure cleaning to get to the point where I could see what was going on, still expecting a hose to be blown.

Now I can see what is going on and run the machine and nothing appears to be blown and no big leaks, one small one by nothing like what I expected. Hydraulic Tank is still 3/4 full so plenty of fluid and stiull no drive or bucket etc.

One thing it does do now is when I run it and then turn it off I get a loud gurgling sound as though the pump is full of air ?

Is there a way to bleed the pump ?

Any ideas or suggestions ?