-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1992 S60 Governor/Actuator

- Thread starter M1687

- Start date

I know its confusing. So I had to look back at my previous post.

I did several scenarios:

The first was everything was hooked up except for the red wire on the actuator. The engine will shut off. (I did not test the anti diesel solenoid because I assumed it functioned)

The second scenario was having everything hooked up as it should be. I had a continuity tester on terminal #1 of the controller. When I hit the estop or key off the light stayed on but got dim a little. The engine will not shut off.

The third scenario I did was I pulled the two red wires off terminal one of the controller and left the wires hooked up to the actuator. When I started the engine the actuator sent the engine rpm to wide open throttle. The engine would not shut down.

Lastly, I separated the two red wires for terminal one of the controller. The one wire that comes from the main harness works as it should. Key on I have power, key off or estop I have no power. The other red wire that comes from CR11 did not have any power with the key on or off.

With all these tests, I was focused on the controller area not necessarily the anti diesel solenoid. I was under the assumption that if the engine shut off, then power was cut off to the solenoid which kills the engine etc.

I did several scenarios:

The first was everything was hooked up except for the red wire on the actuator. The engine will shut off. (I did not test the anti diesel solenoid because I assumed it functioned)

The second scenario was having everything hooked up as it should be. I had a continuity tester on terminal #1 of the controller. When I hit the estop or key off the light stayed on but got dim a little. The engine will not shut off.

The third scenario I did was I pulled the two red wires off terminal one of the controller and left the wires hooked up to the actuator. When I started the engine the actuator sent the engine rpm to wide open throttle. The engine would not shut down.

Lastly, I separated the two red wires for terminal one of the controller. The one wire that comes from the main harness works as it should. Key on I have power, key off or estop I have no power. The other red wire that comes from CR11 did not have any power with the key on or off.

With all these tests, I was focused on the controller area not necessarily the anti diesel solenoid. I was under the assumption that if the engine shut off, then power was cut off to the solenoid which kills the engine etc.

willie59

Administrator

The first was everything was hooked up except for the red wire on the actuator. The engine will shut off. (I did not test the anti diesel solenoid because I assumed it functioned)

The second scenario was having everything hooked up as it should be. I had a continuity tester on terminal #1 of the controller. When I hit the estop or key off the light stayed on but got dim a little. The engine will not shut off.

I've never seen anything like this M, so I'm trying to think outside of the box. The puzzling thing is red wire that goes to terminal 1 of Precision Gov controller is same power wire that goes to terminal on actuator. You can disconnect wire from actuator, everything now works proper, engine shuts down proper. Connect wire to actuator, as it should be, and red wire remains powered up when E stop depressed, engine keeps running.

Logic indicates problem is coming from Prec Gov giving a voltage feedback coming from terminal 4, passing through magnetic coil of actuator, then sending power on to red wire that powers everything. Never seen this before, but the only place I can see feedback coming from is signal from ignition circuit on terminal 3, don't know if it can do that or not, it's just the only place I can see where feedback would be generated.

If all this is true, having Precision Governor repaired/replaced would likely fix your problem. Or, if ya feel like doing something out of the ordinary for the hell of it, install a diode in the wire that goes from terminal 4 to actuator. I'd be curious if that made things work proper, and would basically confirm faulty Prec Gov controller.

VoodooMojo

Senior Member

- Joined

- Jan 18, 2012

- Messages

- 344

- Location

- Baltimore, East Coast USA

- Occupation

- Sr Technical Service Representative

M did say that when he removed the wire from terminal 4, the engine would shut down as it should.

The diode test should give an indication.

It is a PWM signal but will still carry a bit of current.

Do not use less than a 6 amp diode / 200volt PIV (the actuator has healthy coils in it).

The diode test should give an indication.

It is a PWM signal but will still carry a bit of current.

Do not use less than a 6 amp diode / 200volt PIV (the actuator has healthy coils in it).

willie59

Administrator

Yep, I was aware of this Voodoo, never seen a Prec Gov have this reaction myself, just trying to think of something crazy that M could try and make some progress.

I installed the new contact relay(CR11) today and reworked the ground wires for all the relays in the vicinity etc. I have an initial positive result as I hooked everything back up and tied the two red terminal one controller wires together but did not install them on the controller (everything else was hooked up). I turned the key in the on position and tested the continuity on the red wires and had good results. I didn't have time to fire the engine up though and I'm thinking I may send off the controller to have it tested before I do so etc.

One thing I did find and I wanted to hear your feedback on is that the red wire that comes from the main harness and goes to terminal one on the controller I found that it was rubbing on the post of the power relay in the photo below. Not sure if this would be the culprit of my problem or not as I tested this wire by itself not hooked to the controller.

One thing I did find and I wanted to hear your feedback on is that the red wire that comes from the main harness and goes to terminal one on the controller I found that it was rubbing on the post of the power relay in the photo below. Not sure if this would be the culprit of my problem or not as I tested this wire by itself not hooked to the controller.

willie59

Administrator

Anything is possible M, but if that wire were rubbing causing the problem, seems it would always be a problem, not just when wire is connected to actuator, it would keep main power on circuit all the time keeping engine running.

Sending the controller off and having it tested/repaired very well may fix your problem, it's totally up to you to go ahead and do that.

Sending the controller off and having it tested/repaired very well may fix your problem, it's totally up to you to go ahead and do that.

Actuator

Well after three weeks of waiting I finally received a response from Hindley Electronics. They told me one of my trim pots is bad on the controller and also in the upper right hand corner near the outputs there was some bad transistors (resistors?) which I was told is more than likely caused by the actuator? So my question is should I send the actuator in? This was a speculated response from the tech via the salesmen talking to me on the phone. I'm currently having him talk to the tech also. Can this might have been caused by the actuator drawing too much voltage? Maybe me hooking it up and unhooking it while it was energized? Any thoughts? The reman controller will be about $221. A new actuator is about $600. The salesmen wasnt sure if they rebuild the actuators still? I guess myfear is that I hook up the rebuilt controller only to have the actuator fry the controller all over again?

Well after three weeks of waiting I finally received a response from Hindley Electronics. They told me one of my trim pots is bad on the controller and also in the upper right hand corner near the outputs there was some bad transistors (resistors?) which I was told is more than likely caused by the actuator? So my question is should I send the actuator in? This was a speculated response from the tech via the salesmen talking to me on the phone. I'm currently having him talk to the tech also. Can this might have been caused by the actuator drawing too much voltage? Maybe me hooking it up and unhooking it while it was energized? Any thoughts? The reman controller will be about $221. A new actuator is about $600. The salesmen wasnt sure if they rebuild the actuators still? I guess myfear is that I hook up the rebuilt controller only to have the actuator fry the controller all over again?

VoodooMojo

Senior Member

- Joined

- Jan 18, 2012

- Messages

- 344

- Location

- Baltimore, East Coast USA

- Occupation

- Sr Technical Service Representative

Just be sure to always have 12 volts at terminal 1 whenever there is 12 volts at the actuator.

Also be sure to never install terminals 1 and 2 with reverse polarity.

The actuator appears to be ok. Verify that it moves freely without binding.

Also be sure to never install terminals 1 and 2 with reverse polarity.

The actuator appears to be ok. Verify that it moves freely without binding.

I heard back from Hindley and they said they would warranty the controller so I should get it back tomorrow evening. Hopefully Thursday morning I can hook it up etc. Voodoo can you elaborate on terminal 1 and 2 with reverse polarity? Are you referring to the controller or actuator?

VoodooMojo

Senior Member

- Joined

- Jan 18, 2012

- Messages

- 344

- Location

- Baltimore, East Coast USA

- Occupation

- Sr Technical Service Representative

Controller

Seems like I just can't put this issue to bed. I hooked up the new/rebuilt controller and started to follow the adjustment procedures. I didn't get past line 2 or 3 which is verify I have 12v at the battery and controller etc. I have 12v at my batteries and only 10v at terminals 1 & 2 of the controller. I know I remounted my ground screw terminal in the area but what are some of the other causes for only having 10v at the controller? I did install a new positive battery cable from the battery to the relay on the compartment wall. Any thoughts before I check myself into the local mental hospital?

willie59

Administrator

Follow your wiring diagram M, it's the only way you can sort through these type problems. Use a volt meter to check every connection of power wire as it leaves battery. Check at 15 amp breaker, check at terminals of lower E stop, check at terminals of upper/lower select switch, I've seen Telemechanique switch contact blocks cause all sorts of problems from bad contacts inside. You simply follow the current path laid out by the wiring diagram all the way to the governor controller.

Keep in mind, it's normal to have a bit of voltage drop as current travels through a good bit of wiring and connections, but you should search for a good bit of voltage drop through a single component, such as a contact block or from connection to a terminal strip to where wire connects to other side of terminal switch.

Keep in mind, it's normal to have a bit of voltage drop as current travels through a good bit of wiring and connections, but you should search for a good bit of voltage drop through a single component, such as a contact block or from connection to a terminal strip to where wire connects to other side of terminal switch.

Well I thought I made some progress only to run into another brick wall this morning. I had the local Genie Dealer out last week to have a new set of eyes on my wiring problem. He/we discovered a short in the wiring leading up to one of the beacon lights. So I repaired the wiring and sent the Controller back for testing. They told me the "outputs" were once again bad and they highly suggested that the actuator was causing this and/or hooking up the controller with the battery/key on etc. I have always hooked the controller up with everything turned off etc. I tested the resistance on the actuator (3.2 ohms) and did a manual test on it with a battery. Everything seems to check out (No binding etc). Currently I still have 10.5 volts at Terminal One of the controller and I keep ruining the new controllers everytime I hook it up etc. So being back at square one with SOME progress, I'm still left scratching my head and checking wiring. The Genie Tech looked at everything in my control panel and didn't see any issues (key switch, estop, etc). So I'm left with checking all the wiring outside of the panel and leading up to the other components in that circuit. My question is with only 10.5 volts, am I looking for a bad component or a short circuited wire or both? Will a bad component/short circuit cause my controller to ruin the outputs as I keep doing? I did replace the ignition module before all of this happened. Do I need to retest that? Also, is there anyone out there in the Ann Arbor, Mi area that can help?

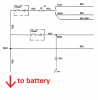

I have a diode question if any one is still out there? In my picture below I have a voltage drop before and after the diode. Is this normal or not? Also can anyone take a look at the diagram and give me their feedback as to why I might have 3.2 volts on the #19 wire when the switch is in the ground control position? Besides another wire short the only thing else I can see in common is the start toggle switches. (Note: #19 wire is for the 12v to platform circuit).

willie59

Administrator

M, check your diagram, follow the voltage backwards toward battery. Go backwards. Start with a volt meter at that upper/lower selector switch, check the voltage at those two bottom terminals. If it's low (that 3.2 for example, follow wire over to E Stop contact at the left in pic, check voltage there. Still low, the red wire goes backward to 15 amp circuit breaker, then it goes back to TB25, then to PR5, ultimately back to battery.

Chase this wire circuit backward toward battery until you find the spot where the voltage on circuit is no longer low, back in the 12V range.

Chase this wire circuit backward toward battery until you find the spot where the voltage on circuit is no longer low, back in the 12V range.

Willie,

The voltage at the two bottom terminals of the selector switch are fine. My problems are with the two upper terminals. The one issue is the voltage drop off the diode as shown in my picture. This wire eventually goes to my controller which is where I have voltage less than my battery voltage. I traced the problem to this diode but I'm not sure if this is the only issue or if this is normal voltage before and after the diode etc.

My second problem is with the wire that feeds 12v to platform off the selector switch. What I found is if you remove this wire from the selector switch and then energize the ground controls I have a voltage reading on this circuit of 3.23v. I'm assuming it should be 0? Initially I thought I had a bad selector switch, this is why I took the wire off etc.

I know this is an unpopular topic/thread but your feedback is appreciated as I'm still working my way through these wiring issues.

The voltage at the two bottom terminals of the selector switch are fine. My problems are with the two upper terminals. The one issue is the voltage drop off the diode as shown in my picture. This wire eventually goes to my controller which is where I have voltage less than my battery voltage. I traced the problem to this diode but I'm not sure if this is the only issue or if this is normal voltage before and after the diode etc.

My second problem is with the wire that feeds 12v to platform off the selector switch. What I found is if you remove this wire from the selector switch and then energize the ground controls I have a voltage reading on this circuit of 3.23v. I'm assuming it should be 0? Initially I thought I had a bad selector switch, this is why I took the wire off etc.

I know this is an unpopular topic/thread but your feedback is appreciated as I'm still working my way through these wiring issues.

willie59

Administrator

Whoa, hold on, you said "I have a voltage drop before and after the diode". If that's true, problem isn't diode.

You're saying you're getting 12V +/- at the bottom terminals (screw heads) of contact blocks? What voltage do you get from the top terminals of contact blocks pictured?

You're saying you're getting 12V +/- at the bottom terminals (screw heads) of contact blocks? What voltage do you get from the top terminals of contact blocks pictured?

Willie,

Yes, the wire with the diode in the picture, when energized, has a voltage drop to 11.66. So you're saying that is not normal and I have other issues?

The contact blocks on the top of the selector switch, when energized individually, are at 12.20v. As I previously stated I had an issue with having a voltage reading on the platform contact when NOT selected. I narrowed that down to the wire that feeds the platform. Today I traced this wire to the platform E-stop where I pulled the two wires off as shown in the picture below. I then tested the voltage at the selector switch and my issue went away. So I'm making some progress. I ran out of time today to figure out the two wires I pulled off the upper E-Stop and where they go etc. They did have a lower voltage, when energized and not hooked up etc. (about 9v). So I think I'm getting closer to my primary issue. It's frustrating working afternoon shift as you have to stop and go to work etc

Yes, the wire with the diode in the picture, when energized, has a voltage drop to 11.66. So you're saying that is not normal and I have other issues?

The contact blocks on the top of the selector switch, when energized individually, are at 12.20v. As I previously stated I had an issue with having a voltage reading on the platform contact when NOT selected. I narrowed that down to the wire that feeds the platform. Today I traced this wire to the platform E-stop where I pulled the two wires off as shown in the picture below. I then tested the voltage at the selector switch and my issue went away. So I'm making some progress. I ran out of time today to figure out the two wires I pulled off the upper E-Stop and where they go etc. They did have a lower voltage, when energized and not hooked up etc. (about 9v). So I think I'm getting closer to my primary issue. It's frustrating working afternoon shift as you have to stop and go to work etc